Every distillery has its own path to success. Some start small with a simple pot still as a craft distillery and they’re happy making a barrel a day or a week. Others start out bottling other people’s juice to get a taste for the spirits business. If they find success they eventually hit a tipping point of either continuing to depend on someone else for that distilled spirit or they choose to take the leap and build their own distillery. For the most part, Luxco, Inc has taken the latter path.

Luxco has been in and around the distilled spirits business since 1958 when they began as a private label bottler serving the needs of distributors, wholesalers and retailers. Since that time, the family owned company has patiently grown into a leading producer, bottler, importer and marketer of spirits with a portfolio of brands including Tequila & Triple Sec, Pearl Vodka, Everclear Grain Alcohol, El Mayor Tequila, Lord Calvert Canadian Whisky and other well-recognized brands. There Kentucky Straight Bourbon Whiskey brands include Rebel Yell, Blood Oath, Ezra Brooks and David Nicholson 1843.

The Luxco bourbon whiskey brands will soon have a new home of their own. In April 2016 the company announced they had purchased 70 acres of property in Bardstown, Kentucky to build a distillery. They are now up to 90 acres with the purchase of 20 adjacent acres. In September of 2016 they announced the name of their new distillery – Lux Row Distillers in honor of their founder Paul A. Lux. The construction project is now well under way. Before we share their construction progress, let’s do a quick check on how they landed here.

Checklist for Building a Successful Bourbon Brand

Everyone has their own secret sauce. In the case of Bourbon there are a few specific things that you need to check off on your “To Do List” to help jump start success. There’s no one single path to distilled spirits success but here’s a partial list in no particular order. You can add your own additions to this list in the comments below.

✔ National Historic Home Place – 18th century home on property.

✔ Family history in the business – Founded 1958.

✔ Winding scenic entrance to distillery – Entry lined with massive oak trees is a bonus.

✔ Location, location, location – Build a distillery in the 40004 zip code, the Bourbon Capital of the World.

✔ Use limestone rich and iron free H2O.

✔ Build within minutes of 95% of the worlds bourbon supply – There’s lot of nearby expertise.

✔ Build with an eye on expansion – Start planning your 1st and 2nd expansion if things take off.

✔ Tourism – Future membership on the Kentucky Bourbon Trail.

✔ Have an existing Kentucky Bourbon brand – The sooner you learn the distribution side the better.

✔ Offer mixed drinks in your tasting room – Not in the plans for this phase.

✔ And of course lots of money – This is a $35 million project.

And it goes without saying that you have to have good juice. Does it have to be made in Kentucky? Of course not, there’s some very good bourbon being made in many states across the country. There was however a recent change in Kentucky law that says, “…to be labeled as Kentucky Whiskey, the spirits must be made in Kentucky “from grains which are cooked, fermented, and distilled in Kentucky.” Know the laws.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

A Behind the Scenes Look at the New Lux Row Distillery

We recently had the opportunity to meet with Tony Kamer, Distillery Operations Manager and John Rempe, Director of Corporate Research and Development to tour the under construction distillery. After we put on our safety glasses, vest and hard hat, we were ready to go.

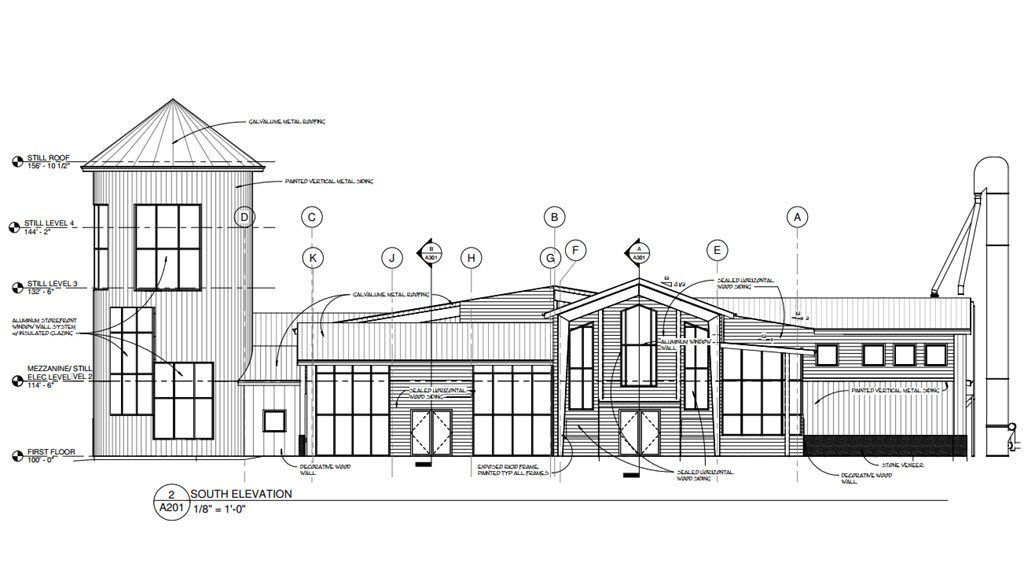

They broke ground on the project in in May 2016. The new distillery will be 18,000 square feet including a 2,200 square foot visitor center and a 1,500 square foot tasting room. There will also be six 20,000 barrel rickhouses with room for more. Architects for the project are Joseph & Joseph Architects. They’ve done several distilleries in the region and across the country. The project is being built by Buzick Construction who is also experienced in distillery construction.

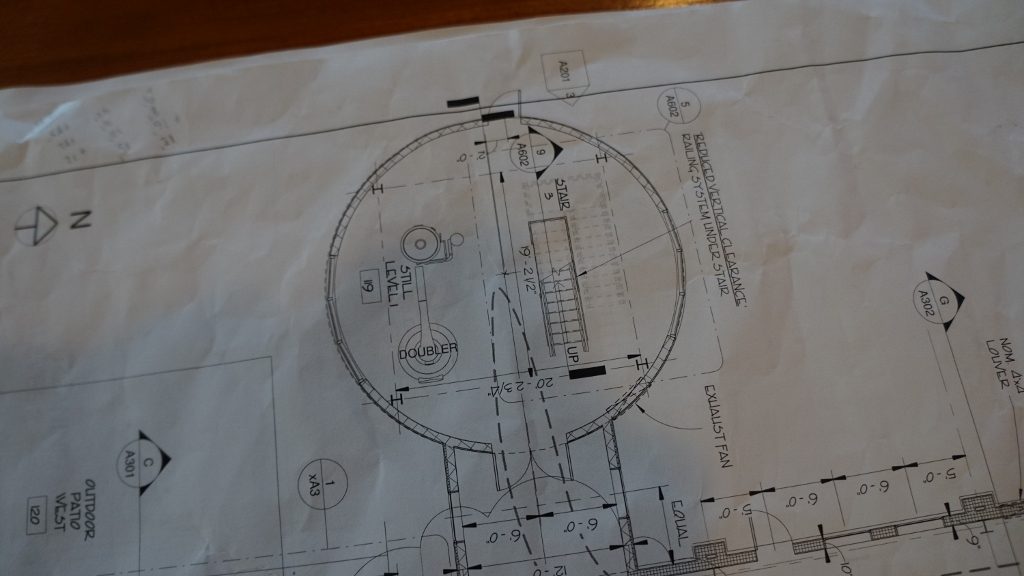

The distillery will be made up of a meal house with three tanks to hold the corn, wheat, rye or barley as needed for various mashbills. From there grains move along to two 8,000 gallon cookers built by Vendome Copper & Brass Company then on to a dozen 8,000 gallon stainless steel fermentation tanks built by Cleveland Welding and Equipment Company. Some are covered and some are open so visitors can watch the fermentation process in action. Next stop is a 10,000 gallon beer well before arriving at the still house. Inside the still house is a 43 foot tall, 36 inch diameter Vendome copper column still with 19 plates. The still and 500 gallon copper pot doubler were both under shrink wrap when we were there. The steam heat for the still and cookers will be provided by a Sellers Manufacturing 500HP boiler. The spirit safe will be installed as they get closer to distillation.

Blending prior to barreling will happen in three 7,050 gallon processing tanks then on to 53 gallon oak barrels for maturation. The barrels will rest in one of six 20,000 barrel three story rickhouses. One is complete and the others will be built as needed. There’s plenty of room on the 90 acres to add more barrel warehouses.

One Million Proof Gallons Per Year Starting January 2018

Once completed, the new distillery will be able to produce 1 million proof gallons per year. That number can grow with the addition of fermentation tanks and extra shifts. John and Tony expect to be doing water runs through the equipment in December and start true distillation in January 2018. The distillery is expected to be open to guests in Spring 2018.

Related Stories

New Distillery from Luxco Coming to Kentucky Bourbon Trail

Luxco Unveils New Kentucky Distillery Name as Construction Continues

Photos from Lux Row Distillers Construction Site

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.