When you decide it’s time to expand your distillery operation you have to make a decision to build new from scratch or add on to your existing distillery. They each have their own unique set of challenges. In the case of Wilderness Trail Distillery in Danville, Kentucky they first opened their distillery in 2013. As they found success with their startup craft spirits distillery they quickly outgrew their original space and purchased 22 acres on the outskirts of town to build a new distillery. They completed that project and started distilling in June 2016. At the time, they expanded their production capacity from about two barrels a day to 12 barrels a day. Once they got their new operations running smoothly they added a second shift and bumped production to 24 barrels per day. Even before their shiny new 18″ diameter, 36′ tall copper column still achieved its full patina Wilderness Trail Distillery co-founders Shane Baker and Dr. Patrick Heist started talking about their next expansion. Fast forward one year and they officially announced their plans. They weren’t moving but they were expanding, big time.

A $10 Million Investment and Expansion to 36,000 Barrels a Year

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

In June 2017 Wilderness Trail announced they would be expanding their distillery production from 24 to 150 barrels per day. That’s a jump from 6,000 to 36,000 barrels per year. This is a substantial jump for a distillery that just four years ago was running its entire operation on a 250 gallon electric pot still. According to some back of the napkin analysis by Kentucky Bourbon Hall of Fame member and author Chuck Cowdery, this will make Wilderness Trail Distillery the 14th largest bourbon distillery in the United States. To put this in perspective, Cowdery’s estimate will make Wilderness Trail larger than industry brands like Lux Row Distillery (now under construction), Michter’s Distillery and Angel’s Envy Distillery. That’s some pretty impressive company.

Renovation vs. New Construction

Seeing as how the distillery just moved to this multi acre property there really wasn’t any consideration of moving but now they had to build around an existing distillery. If you’ve ever done home renovations, you know that half the time is spent getting the old stuff out of the way to allow for the installation of the new stuff. Not to mention, you still have to live in the house while all the renovations are happening. Such is the case with this project; the distillery has to keep up with mashing, fermenting, distilling and barreling while expanding capacity 6X.

Business as Usual – Not

The day I was there for the delivery of the new still was basically a regular work day except for the fact that there was a 200′ crane on the grounds waiting to install the new 36′ column still that was now en route.

While the crane was getting set up a farmer was backing in under the boom to pick up a load of spent grain to take back to his farm to feed his cattle. Before you knew it, he picked up his load, disappeared and then was back for another load. Next, one of the distillery workers tracked me down to ask if my vehicle was the one parked near the grain silos because there was a truck on the way with a load of corn. I said it was so I moved the car. Turns out I didn’t move it far enough because when I went to get in the car at the end of the day I couldn’t see out the windshield because it was covered in corn dust (lesson learned.) After parking the car I hopped out and had to quickly dodge a garbage truck that was making a pickup that day.

All those new barrels of whiskey require a place to store them. There was a full crew on the other side of the pond building a third barrel warehouse on the property. Once completed, that warehouse will one day hold 20,500 barrels of bourbon. The new warehouse is expected to be completed by January with another one scheduled to begin in another five months. The angels in this neighborhood are looking down, smiling and patiently waiting. Let’s just say, “There was a lot going on!”

The New Distillery and Redundancy

Nestled between the existing still house and the pond was another project. That’s where a collection of shiny new stainless steel distillation vats were now sitting. It’s basically another distillery next to the original with the exception of the column still. While you could hear hammers over by the rickhouse construction, you could hear the pinging of steel and the non-stop sound of beeping high lifts moving up and down as they were laying the steel to construct the new building around the vats.

The building going up here will be home to two 10,000 gallon cookers, six 20,000 gallon fermentation tanks and a 25,000 gallon beer well. All the tanks were manufactured by Vendome Copper & Brass Works. When I asked Shane why he chose to use Vendome equipment throughout he quickly offered up an anecdote.

“Vendome is kind of like eating your first filet mignon, once you’ve had it; it’s hard to go back to chopped steak.”

~ Shane Baker, Co-Founder Wilderness Trail Distillery

A lot of the design for the new distillery equipment was based on their experiences over the last year of distilling. They occasionally had a piece of equipment break down and discovered they had some choke points. A major design requirement for the new project was redundancy.

The new setup will have one 300 HP boiler for the still and one 200 HP boiler for the cooker. These custom made boilers from Sellers Manufacturing are unique in that they are clean steam boilers. This means that no chemical additives to treat the heated water will ever touch the cooker or the still making for a cleaner spirit.

Shane explained the thinking and design behind the new distillery. “The new design not only gives us independent operation of cooking and distillation but anytime a boiler were to go down, we could gate it over and run the other half of the operation so we’ll always have steam.”

“We put in two 10,000 gallon cookers instead of one large 20,000 gallon cooker which it didn’t make any sense to put that in or just a single 10,000 gallon cooker and a drop tub. Actually, after we looked at a drop tub, you want to be able to evacuate your cooker, get it in the drop tub and let it cool down while you start the next cook. We looked at that but the drop tub was basically another cooker, it has an agitator, coils, it has everything but a sparger and thicker walls. Outside of that it was identical so we decided to go with a second cooker. That way, we’ll have two cookers, a backup, you can do two cooks on one shift with one cooker but again, redundancy. What we’ll do now is we’ll be able to do the full operation in one cooker, not drop it to a drop tub so while we are cooking there and cooling simultaneously we’ve already started the second cook independently so back to back, we’ll have two cooks that will fill your 20,000 gallon fermenter. We have six 20,000 gallon fermenters, a single 25,000 gallon beer well and two 8,000 gallon spirit tanks, one is a high wine tank and the other is a three container system tank. We put the tanks in first and then we’ll build the building around them.”

Arrival of the 36′ Column Still, Beer Pre-Heater and the Condensers

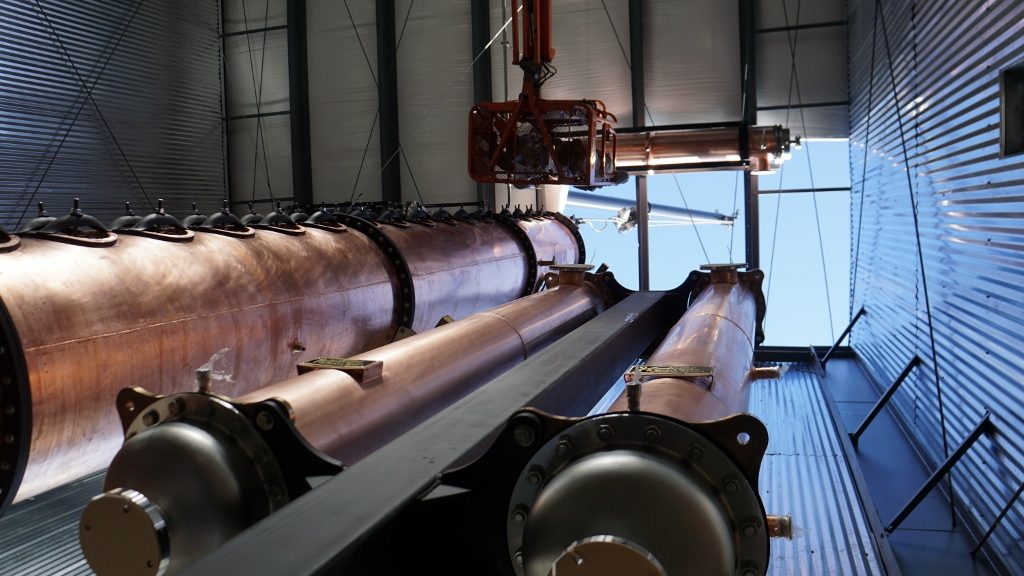

With a chill in the air and a 10 mph breeze the still finally arrived after an 85 mile trip from Louisville to its new forever home in Danville. The new still uses a similar design to the existing 36 foot, 18 diameter copper column still that’s been in use for the last year and a half except like a McDonald’s lunch, it’s super sized. The new 7,000 lb. Vendome copper column still measures 36′ tall with a 36″ diameter and 19 plates. It’s made up of 15 stripping plates, one detrainment plate and three rectification plates. Riding along with the still was a 72″ copper beer pre-heater designed for 40 to 42 gallons per minute feed rate and a pair of condensers.

Unlike the stainless steel vats that were dropped in place and then are having a building put up around them, this equipment was going inside the existing distillery. The crew had to open up the roof in order to drop the new equipment into place. All this was happening while the other still was in operation. Dropping tons of equipment through a tiny hole in the roof from a 200′ crane with a slight breeze in the air is no simple operation. Many people told me that day that crane operator Kenny Berryhill from Buzick Construction was the best in the business. I heard he could set a hard hat on your head with that 200′ crane. I’ll take your word on that one!

Watch the video to see the entire process from unloading off the truck bed to flying through the air to being bolted to the floor and take a look at the photos below to see the entire operation.

When Will Distillation Start?

Shane said, “Hopefully, by the end of the month everything will be under roof. It will definitely be done by the first of the year. We are on schedule to be distilling late February or the 1st of March.”

Photos of the Aerial Delivery of the Column Still, Beer Pre-Heater and Condensers

Click on any image to enlarge.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.