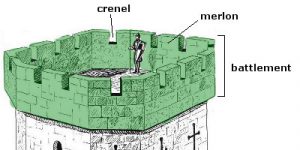

A visit to the Old Taylor Distillery located along Glenns Creek in Millville, Kentucky is like a walk back into history. The distillery originally founded in 1,885 by Colonel E.H. Taylor, Jr. that once produced 1,000 barrels of bourbon a day has been silent since 1972 but that’s all changing. This once majestic castle-like distillery and its surrounding structures including a one of a kind 534′ rickhouse that all once sold for salvage are coming back to life.

But what about the “Key”? A visit to the peristyle covering the “Great Spring” gives way to a 140,000 gallon spring fed pool of limestone water. Upon closer inspection you’ll see the pool is shaped like a key. It seems Colonel Taylor said the water was the “Key to the bourbon.”

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Related Story

Castle & Key Distillery Rising from Ruins After Old Taylor Distillery Narrowly Escaped Wrecking Ball

The Sounds of Progress

The sounds of shovels, welders, torches, backhoes, hammers and saws have been heard around the grounds almost daily since the restoration of the distillery began back in 2014.

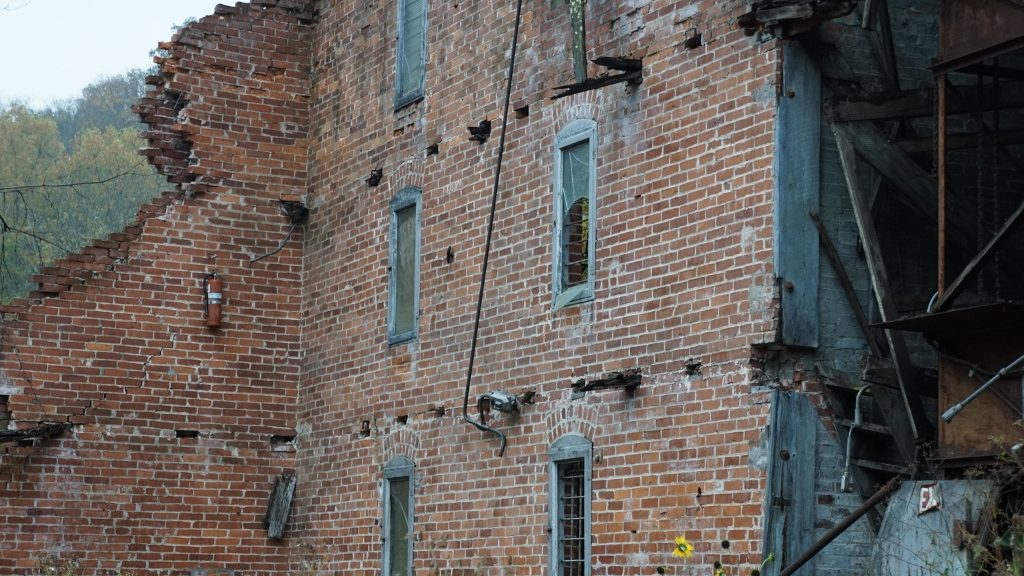

Unfortunately, Barrel Warehouse A was too far gone and had to be torn down. Not to worry though, as much of the heartwood pine from the late 1,800s that could be salvaged from the racks was kept and used for other purposes around the distillery. The actual ground where the warehouse once stood is now a nursery to 39 different herbs like mint, basil, sage, lavender, rosemary, thyme, and chamomile that will soon be used to craft a variety of seasonal gins at the distillery. Take a look at the photo below where you can see a fire extinguisher frozen in time hanging on the ruins of the second floor of what’s left of this warehouse.

Click on any of the images below to enlarge.

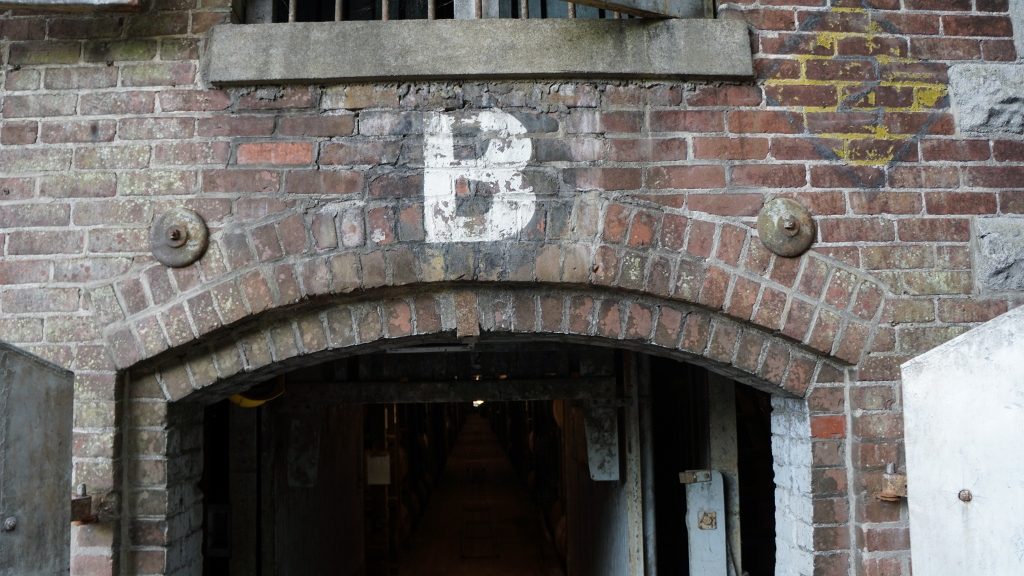

“(Warehouse B) was really our first big project when we came on property,” according to Brand Ambassador, Brett Connors. “When we took over in 2014 … I joke on the first tour you were recommended to bring cowboy boots, a machete and a flashlight which they very sincerely meant. Even this road we’re on we had no idea it was here…everything was essentially a four wheeler track, it was that overgrown. There was no electricity on property. This roof had pretty substantial damage to it and it had to be re-roofed.”

Barrel Warehouse B is the longest rickhouse of it’s kind in the world. It measures a whopping 534′ from gutter to gutter and can hold some 33,000 barrels. The roof had some holes but the building was otherwise solid. Once repaired this rickhouse is now open for business and already holds barrels of maturing bourbon and rye as a part of Castle & Key’s business plan to rent out warehouse space to other distilleries. You can already hear the sounds of barrels rolling as they make their way into what Brett calls “The Man Eater” because once you start rolling barrels down this 500+ foot barrel runway, there’s only one way in and out of this place.

You know the rickhouse is long when it says, “THE OLD TAYLOR DISTILLERY WAREHOUSE” in large block letters down the side of the building. You can see a partial photo in the photo gallery below. It’s so massive I couldn’t get it all to fit in one shot.

Barrel Warehouse E sits in the center of the distillery grounds and is a more modern concrete barrel warehouse that was built in 1953 by National Distillers. This massive concrete building can hold 62,000 to 65,000 barrels. This warehouse sits there empty and is eerily silent except for the echoing of our footsteps as we walked through this monstrous eight story dull gray structure.

The Sounds of Wedding Bells

Though not yet open, the sound of wedding bells have filled the air here as the gardens have already played host to a few wedding parties. The bride gets to spend her pre-wedding time in the one-time yeast house that’s been converted to a bridal suite right next to the fairy tale castle.

The wedding party can split their time between the sunken garden and the peristyle. When the Castle & Key team first took over the property the sunken garden was referred to as the “Snake Pit.” That soon changed when they partnered with famed landscape designer Jon Carloftis who transformed this neglected area into a garden that now attracts butterflies and tourists peering over the fence. The results are magnificent with the lush green grass, a koi pond, hydrangeas, magnolias, and an array of 100 year old taxus yews. I used to think the only way to trim a yew was by removing it. I was wrong.

And on the other side of the distillery is the peristyle that sits over the great spring. The peristyle with its mixed Roman and Greek styling was built between 1906 and 1909 by Col. Taylor for entertaining tourists. He used to love to host lavish Derby parties on these grounds. The random strings of incandescent lights hung from the open rafters shimmer in mid-day sun and the sound of water running down Glenns Creek make this an enchanting stop on the tour. Hiding under this roof is 140,000 gallons of spring fed limestone, acid-free water that will soon make its way into the bourbon, gin and vodka of the distillery.

The Sounds of Milling Grains

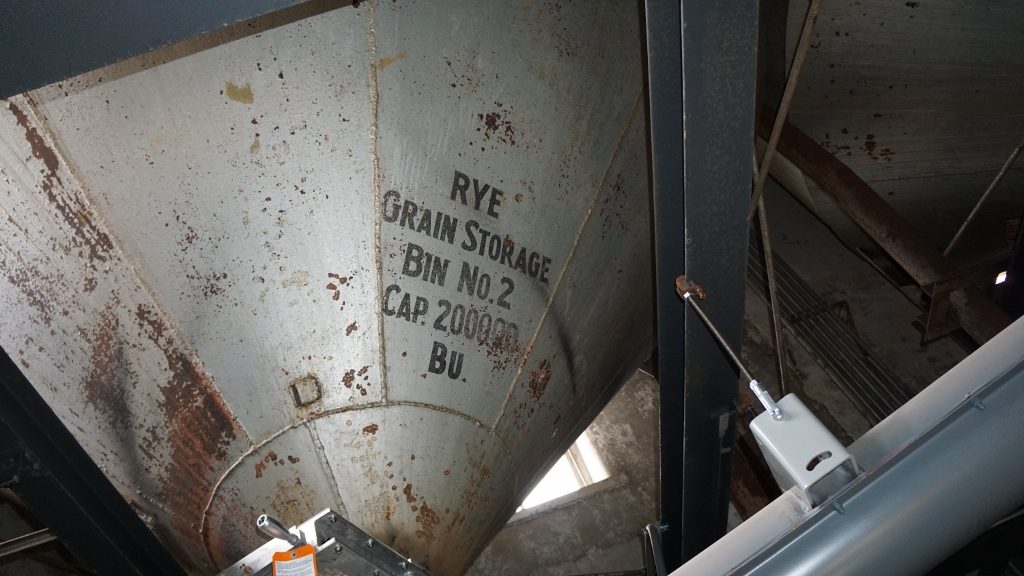

One of the recent milestones was the first delivery of grains. The grains make their way from a grain auger at the back of the distillery into a pneumatic grain carrier to the new hammer mill. Though not in use, one of the two original grain mills sits right next the new equipment as a good reminder of the distilleries past. This room can get extremely loud. Once ground, the grains make their way to the refurbished grain bins clearly marked for corn, malt and rye. From here they make their way to the first floor of the distillery to the grain scales before heading to the cooker.

The Sounds of Distillation

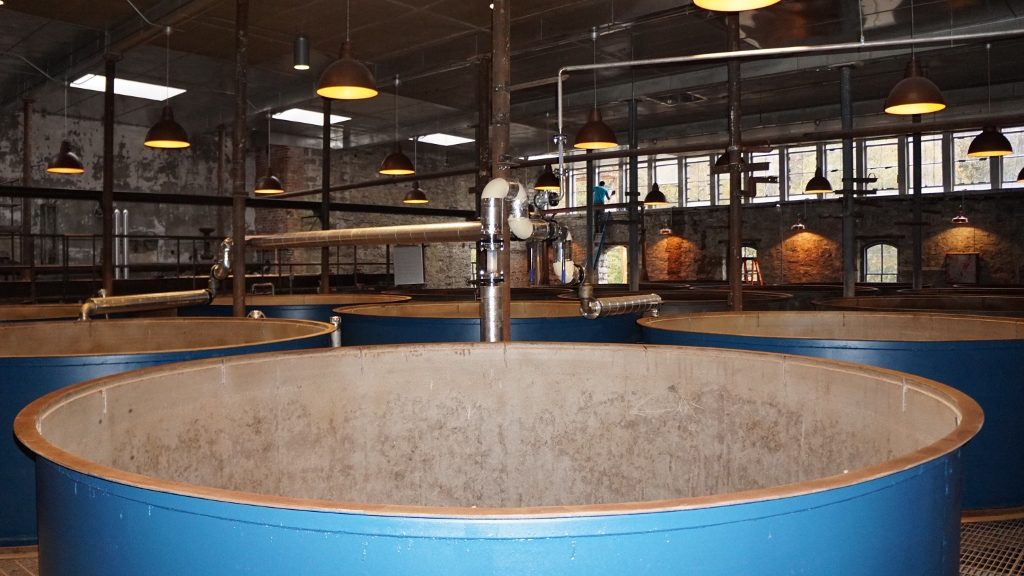

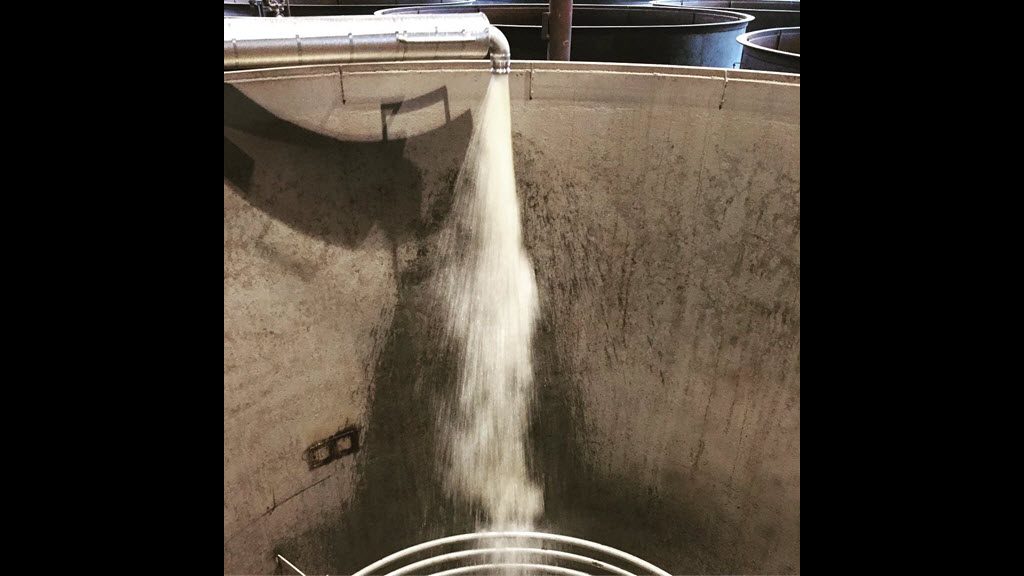

Now getting down to business perhaps the best sound is that of a test batch of limestone water pouring into the cooker and then on to one of the 11,000 gallon fermentation tanks that hasn’t seen a drop of water (except maybe through a once leaky roof) in 44 years. There are a total of 15 fermentation tanks. Six of these tanks have been refurbished with fresh stainless steel linings, coils to control temperature and an impeller that will soon move a cooked mixture of water, yeast, corn, rye, wheat and malted barley. Master Distiller Marianne Barnes has been testing small batches of mash for bourbon, gin and vodka distillation in her lab for many months.

The stills are patiently waiting their turn for testing. The collection of brand new Vendome Copper and Brass Works stills are mostly covered by the shrink wrap that has protected them since the day they were delivered. The two new stills replace the old 72″ diameter column still that used to generate 400 to 1,000 barrels of bourbon a day. The new stills include a 50′ tall by 24″ diameter copper still with 20 plates for making bourbon along with a 40′ tall by 17″ diameter stainless steel still that will be used to make vodka and gin along with a 375 gallon copper pot doubler. Looking at the stills it kind of looks like your little sister couldn’t wait for Christmas and she just had to peel back part of the wrapping paper that covers her soon to be favorite group of shiny copper and stainless steel toys.

You can’t hear the sound of steam rumbling through the pipes or the thumping of the doubler yet but that day will soon be here.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.