Coopers, barrel makers and distilleries are always looking for new ways to make the best bottle of spirits. They experiment with the grains, the peat, the proof, the yeast, and many more things including the barrels. The barrels contribute a lot to the flavor of the spirits that are in them. The “Master Distiller’s Rule of Thumb on Flavor” says that what makes up the final flavor of a whiskey is as follows: 10% Yeast Strain, 15% Distillation, 25% Small Grains and 50% Maturation. The maturation includes the type of barrel, barrel size, time in the barrel, location in the warehouse and several other variants.

Craft distillers and large distilleries experiment with barrels all the time. A recent Buffalo Trace Experimental bourbon tested the effects of infusing infrared light inside a barrel before it was charred and filled with whiskey and aged for 6 years. For those of you who like to get under the hood and find out more about “How’d They Do That”, here are the details of a patent that was applied for in 2008 for a portable apparatus to toast barrels.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Apparatus and Method for Toasting of Barrels

Publication number: US 20100124725 A1 | Filing Date: November 14, 2008

Abstract

The present invention relates to an apparatus and method for toasting a barrel, in particular, toasting the inside surface of an oak wine barrel. The invention is intended for use in a mobile wine barrel reconditioning system, however, may equally well be used in the manufacture of new barrels. The toasting apparatus includes a plurality of radially disposed infrared heating elements configured to be insertable and removable from inside said barrel, and a means of rotatably oscillating said heating means by a predetermined angle to facilitate uniform heating of said inside surface.

Background of the Invention

In the production of barrel staves, oak trees are harvested and the wood is cut or split into shape to be stored and dried for varying lengths of time, up to approximately three years. An oak barrel is formed from these dried staves, with each stave possibly originating from a different oak tree with a different age and moisture content. Oak wood is used for barrels as it contains certain aromatic compounds desirable for wine or other alcohols stored within the barrels. These compounds provide the wine with qualities such as vanilla, smoky and spicy flavors and aromas. The toasting process exposes more of these desirable flavors and aromas in the oak by caramelising sugars, reducing tannin and bitterness, and creating aromatic aldehydes.

Prior to a cooper toasting an oak barrel as an individual and separate process, the staves were traditionally subjected to a heat source in order to enable the construction of the barrel. The staves would be heated and moistened so that they could be more easily bent and metal bands would then be applied to form the barrel shape. At some stage during the history of barrel making, coopers and wine and spirit-makers discovered that the toasting process enhanced the flavour of the wine produced and hence they sought to develop processes where this enhanced flavour was consistently achieved.

The toasting process typically involves placing a barrel over a heat source, generally a furnace, for a particular length of time. The heat source applied to the interior surface of the barrel alters the chemical composition of the oak wood, bringing out different flavors and aromas. Different compounds are released or increased in concentration within the wood depending on whether these compounds were initially found in the wood and the toasting intensity and duration. The toasting intensity, or temperature of the target surface, is of particular importance in producing these compounds and for consistency, the temperature needs to be monitored.

The flavors and aromas, formed by the chemical compounds found in the oak after toasting, then become available for extraction by the wines or alcohols stored within the barrel. The amount of flavors and aromas found in the wood depends on the extent that this chemical alteration process has permeated the wood and is determined by the length of time the oak is subjected to the heat source, as well as the intensity of the heat source and the moisture content of the wood.

Wine and spirit-makers are seeking deeper penetration depths for the chemical alteration of the wood as this allows for more flavors to be extracted over a longer period of time. It has been found that up to 70% of the oak’s flavors are extracted from the wood in the first year of aging wine in that barrel, with the remaining flavors surface extracted at an exponentially reducing rate.

You can learn more about barrels and aging in these related stories.

How Location in a Distillery Rackhouse Effects Proof

Part 1: Understanding Oak Barrel Maturation – Know Your Casks

Part 2: Understanding Oak Barrel Maturation – Maturity is Not Age

Part 3: Understanding Oak Barrel Maturation – Location, Location, Location

Please help to support Distillery Trail. Like us on Facebook and Follow us on Twitter.

Description of the Drawings

The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate several implementations of the invention and, together with the description, serve to explain the advantages and principles of the invention. In the drawings:

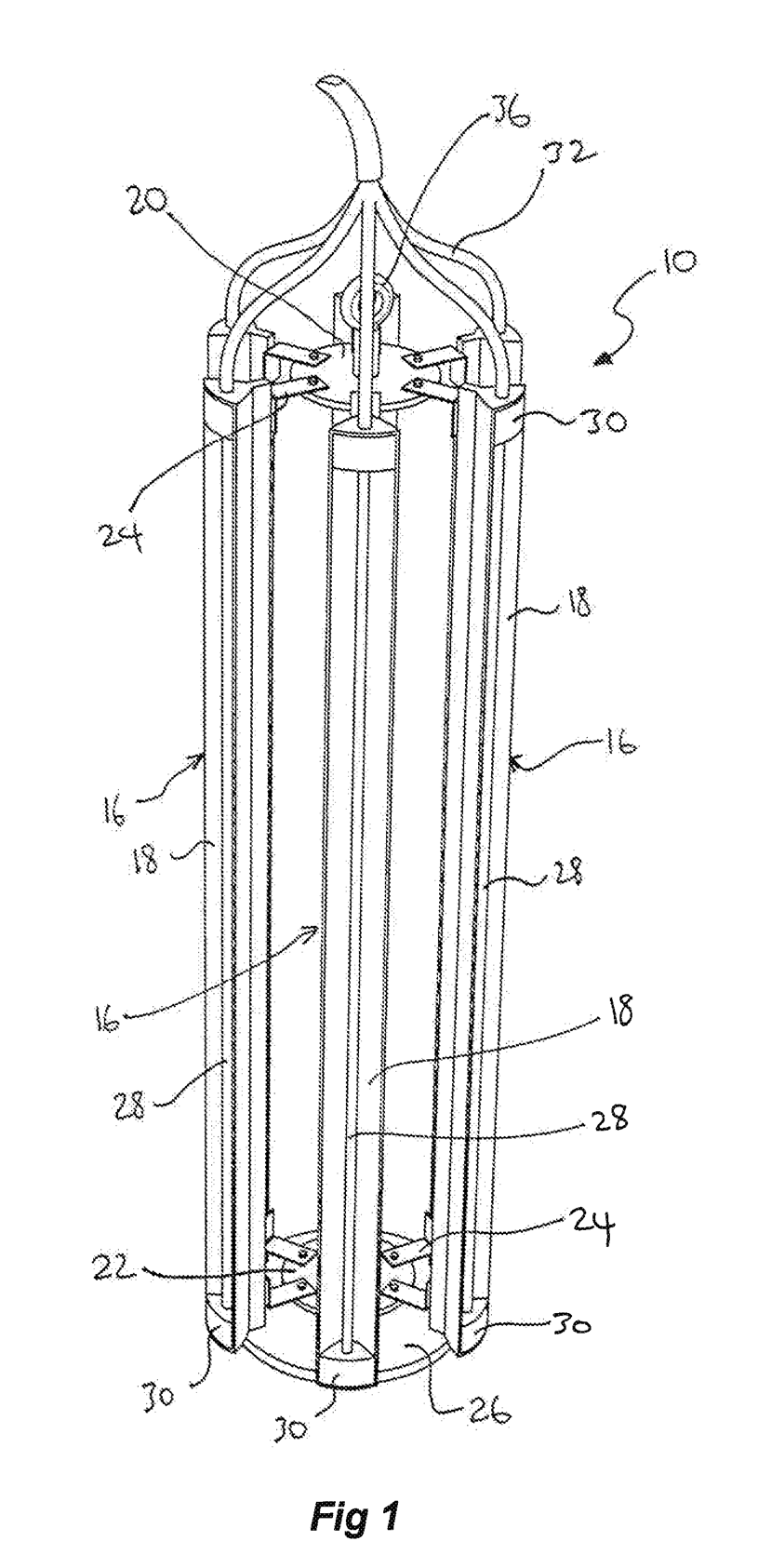

FIG. 1 illustrates a perspective view of an apparatus for toasting a barrel in accordance with the present invention;

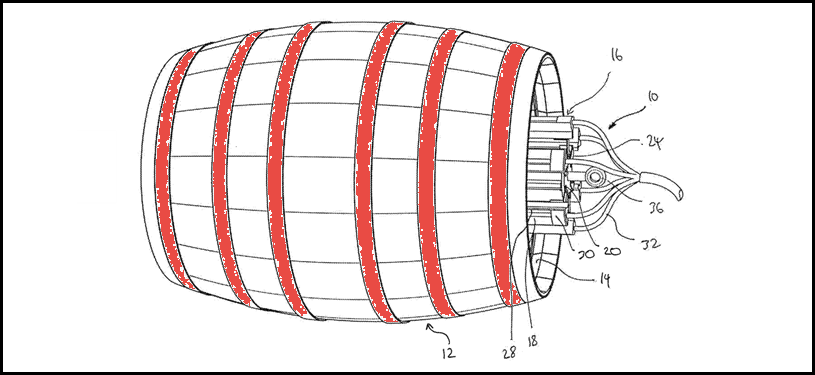

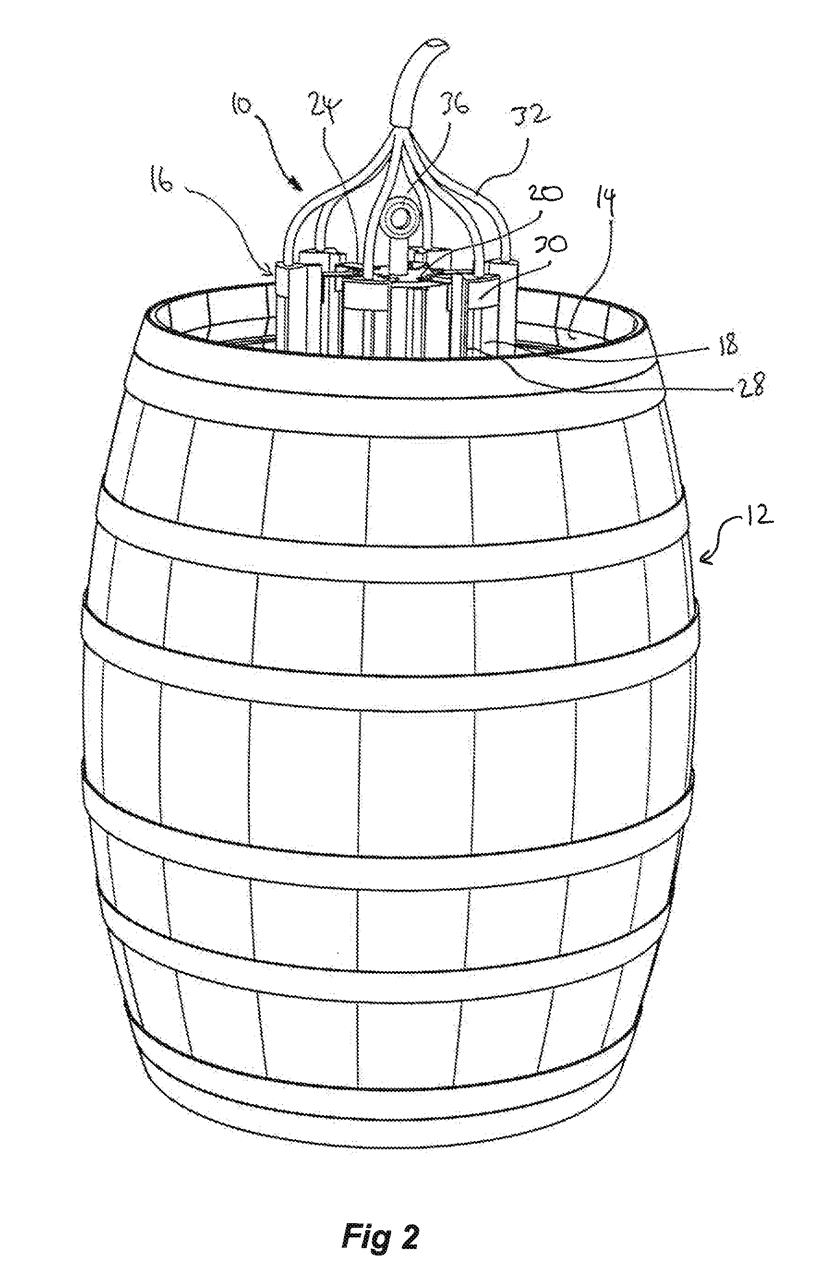

FIG. 2 illustrates a perspective view of the toasting apparatus of FIG. 2 when placed inside a barrel ready for use;

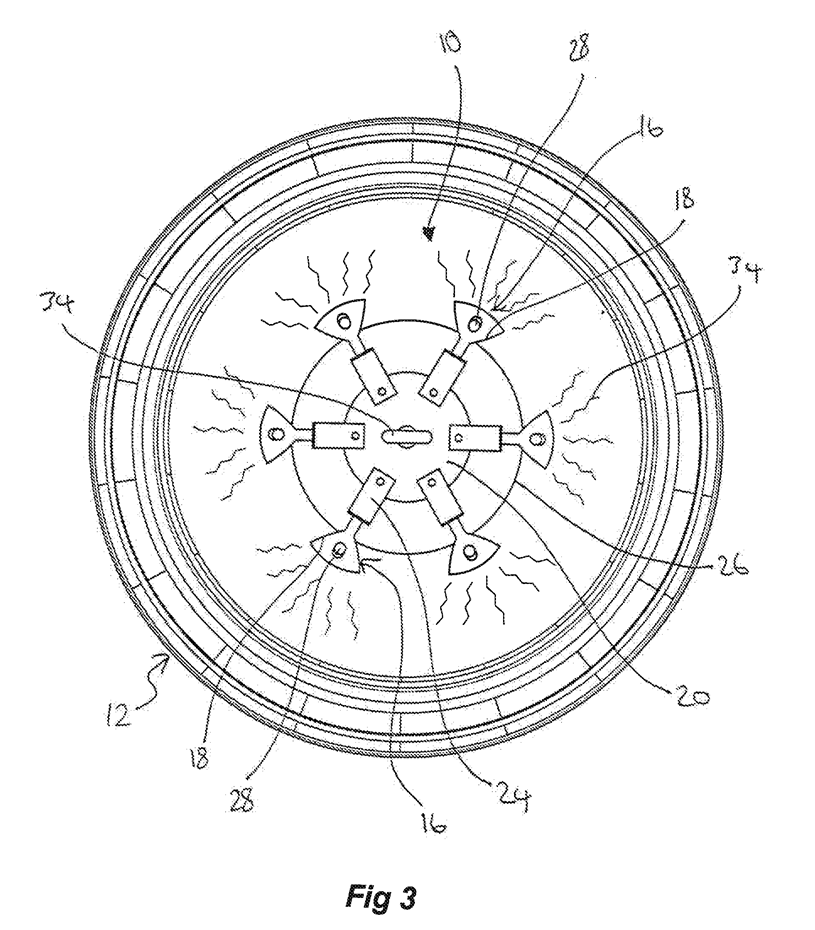

FIG. 3 illustrates a top view of the toasting apparatus and barrel of FIG. 2 during operation; and

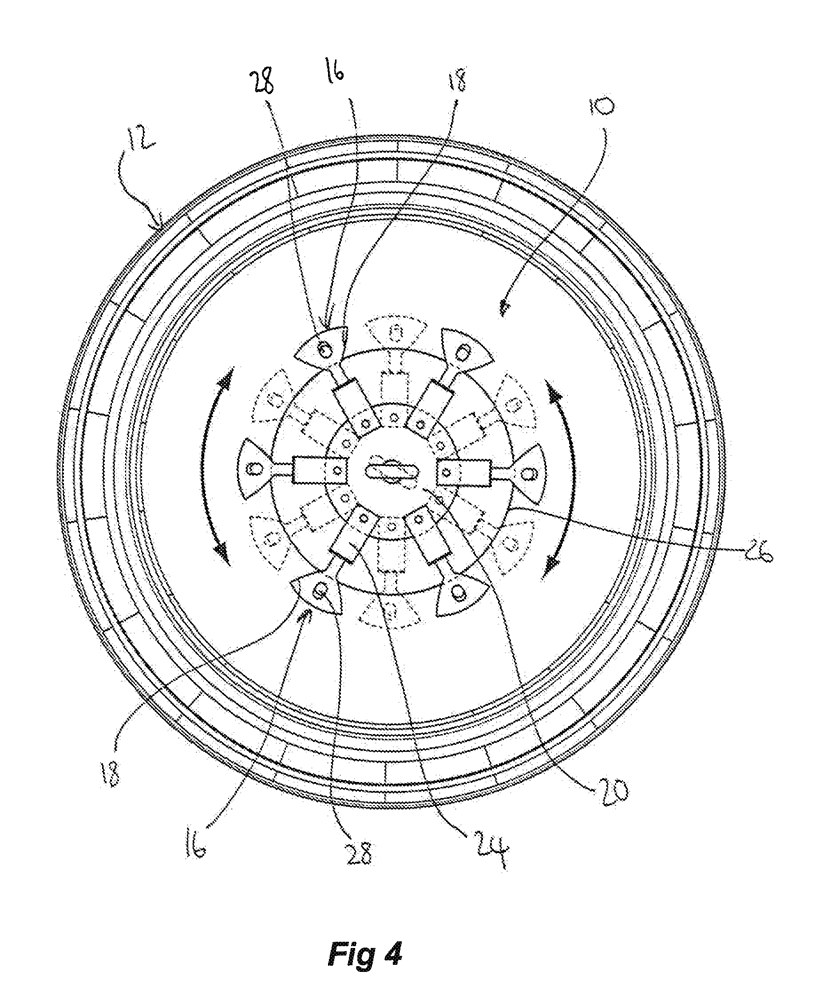

FIG. 4 illustrates a top view of the toasting apparatus and barrel of FIG. 2 and, in particular, the oscillatory motion of the infrared heating elements.

Resources: Apparatus and method for toasting of barrels