Wet staves being heated over an open flame to aid lamination (bending). Cognac Cooperage.

If there is one thing that we all go a bit crazy for, it’s oak matured booze. Even if you’re not a big spirits lover, odds are good you’ve indulged frequently on other such oaked products like balsamic vinegar, Worcestershire or Tabasco sauces. For those who have discovered the world of a well-aged whisky, tequila, brandy, rum or fortified wine, it’s an appreciation easily bought by a bottle carrying buzz terms like extra añejo, solera, single barrel, cask strength, sherry finish or paradise. But what do we really understand about the influence of the oak barrel?

Part 1: Understanding Oak Barrel Maturation – Know Your Casks

Part 2: Understanding Oak Barrel Maturation – Maturity is Not Age

Part 3: Understanding Oak Barrel Maturation – Location, Location, Location

Anyone who has ever attended a whisky masterclass might have had further terms like vanillin, tannin, lignin, lactone, alligator char, conditioning– and something about ‘greedy angels’ – all thrown at them by an overtly gregarious brand ambassador. It’s a language few understand and while the science may be more than a little confusing, the results are anything but. As age statements are being removed more and more from bottles [see: The Oak Conundrum], understanding oak selection and cask finish is becoming more and more important.

Despite archaeological evidence placing the art of the ‘cooper’ as far back as 100 B.C., the wooden cask has evolved little over the last two millennium. The ‘why’ lies not in the latency of technology but rather its modern rebirth as the best tea bag in the world.

When the Romans eventually acquired the skill of coopering off the Gauls around third century AD, it was with the promise of cheap manufacture and improved strength which saw the wooden barrel replace the traditional clay amphora’s of old. And it would have ended there if early cognac, navy rum and American whiskies weren’t forced to spend long periods of time sitting in oak casks, in hot climates. Time proved to be the secret ingredient. Previously robust edges were rounded off, flavors of vanilla and toffee developed beyond the limitations of the raw ingredients and a golden hue was imbued throughout the liquid as if in recognition of this magical transformation.

In an attempt to understand more behind the mysteries of maturation, following is the first of a three-part series exploring the importance of oak, the different casks they’re made into and what really takes place inside them.

Stay Informed: Sign up here for our Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Part 1 – Know Your Casks:

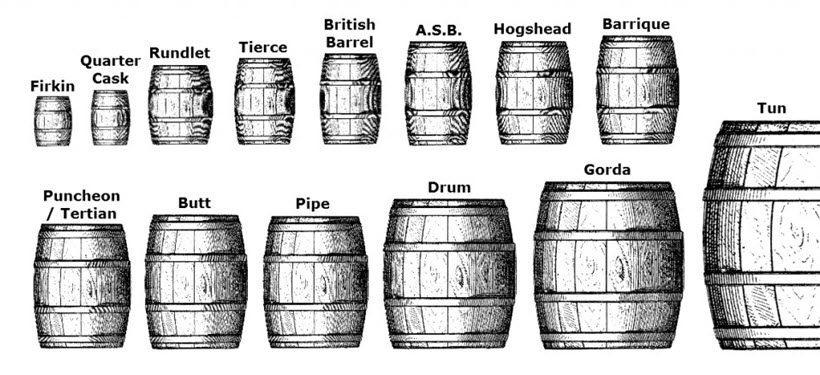

[NB: All cask volumes are rounded to the nearest whole number. Exact volumes can vary on cask use and between traditional and modern cooperage’s.]

Firkin: 41 litres / 11 US gallons

Taking its name from old Middle Dutch for “fourth” implying a quarter of the size of a British Barrel. Traditionally used for dispensing cask ale

Quarter Cask: 50 litres / 13 US gallons

A quarter of the size and proportion of an American Standard Barrel generating a higher wood to liquid ratio. Used for rich oak finishes in Scotch and American whiskey

Rundlet: 70 litres / 18 US gallons

Roughly half the size of a British Barrel. Traditionally used to transport wine

Tierce: 160 litres / 42 US gallons

Closest cask in volume to that of a modern oil drum and one third of a Pipe. Traditionally used to transport wine, mature rum or store salted goods

British Barrel: 160 litres / 43 US gallons

Roughly half a Hogshead. Traditionally used to store ale or lager

Kentucky straight bourbon A.S.B’s maturing in a Woodford Reserve rickhouse. Courtesy of Wiki Commons

ASB Barrel: 200 litres / 53 US gallons

The ASB – American Standard Barrel is used throughout the US whiskey industry after which most are exported for reuse in maturing other spirit types including rum, tequila, Scotch and Irish whiskies

Hogshead: 250 – 300 litres / 66 – 79 US gallons

The most popular cask used in maturing Scotch and Irish whiskies commonly consisting of rebuilt ASB’s from the US which have already held American whiskey. With a slightly smaller oak to liquid ratio, it’s believed that Hogsheads react better to the cooler Scottish climate. Twice the size of a Barrel, half the size of a Butt, quarter of a Tun. Also used in wine and beer

Standard barrel used for old French wine and cognac although at two different volumes. Traditionally coopered with wooden hoops instead of metal.

Barrique: (cognac) 300 litres / 79 US gallons & (wine) 225 litres / 59 US gallons

Puncheon or Tertian: 450 litres / 120 US gallons

Also known as a Tertian from the Latin for “third” implying a volume roughly one third of a Tun (330 litres) although modern day puncheon’s are closer to 500 litres. The modern rum industry favors a short, fat puncheon with thick staves known as aMachine Puncheon while the sherry industry prefers a more traditional tall, slim puncheon with thin staves called a Sherry Shape Puncheon.

Butt: 500 litres / 132 US gallons (y)

Twice the size of a Hogshead, tall and narrow with thick staves and a nice set of hips true to its name. Commonly used for sherry

Pipe: 650 litres / 172 US gallons

Tall cask yet stockier and rounder than a Butt with thick staves. Commonly used for port

Drum: 650 litres / 172 US gallons

True to its name, short fat and dumpy with wide staves. Common cask for Madeira wine

Gorda: 700 litres / 185 US gallons

Commonly used in North America for the marrying or vatting of different whiskies

Tun: 982 litres / 250 US gallons

Roughly twice the size of a Butt and equal to four Hogsheads. Traditionally used for the fermentation of beer or marrying of spirits. Designed to represent one perfect imperial ton of liquid.

It’s believed that at any one time, 20 million oak casks lie maturing in bonded warehouses throughout Scotland. Of these, 90% are said to have come from America. And with global demands for Scotch outstretching its current supply, there is added pressure on American whiskey distilleries to supply them with high volumes of ex-whiskey casks.

According to digital magazine Drink Spirits, a single qualified worker at the Brown-Forman Cooperage in Louisville, Kentucky can assemble up to 500 barrels a day, creating a total cooperage output of near 2,000 new American oak barrels each working day. But they’re not even close to the biggest. Fourth generation owned Independent Stave Company holds status as the largest cask manufacturer in the world and the exclusive supplier of new American oak casks to global spirit companies Sazerac, Beam-Suntory, Diageo, Heaven Hill Distillers and Wild Turkey. With two large American cooperage’s as well as an additional three internationally (Australia, Chile and France) the I.S.C. also operate four state-of-the-art stave mills which source the finest oak from the forests of Central Europe and the American Midwest. That said there is only one distillery in the world that makes its own barrels.

Classified as a Tennessee whiskey, Jack Daniels is limited by law to using only new American oak barrels to mature their annual yield of 24 million US gallons. In return the company shares more ex American whiskey barrels to the global spirit industry than any other brand.

Jack Daniel’s: The Birth of a Barrel

With an increased number of cask finishes selling to the delight of Scotch drinkers, more and more Irish and American whiskies are also giving it a go (see Angels Envy Rum Finished Rye). And with so many different barrel types filled by so many different spirits and beverages around the world, whisky has never offered such a range. But are some of these finishes just hiding a younger mass-produced spirit underneath? With the angels getting more than their fair share, as always, the devil is in the detail.

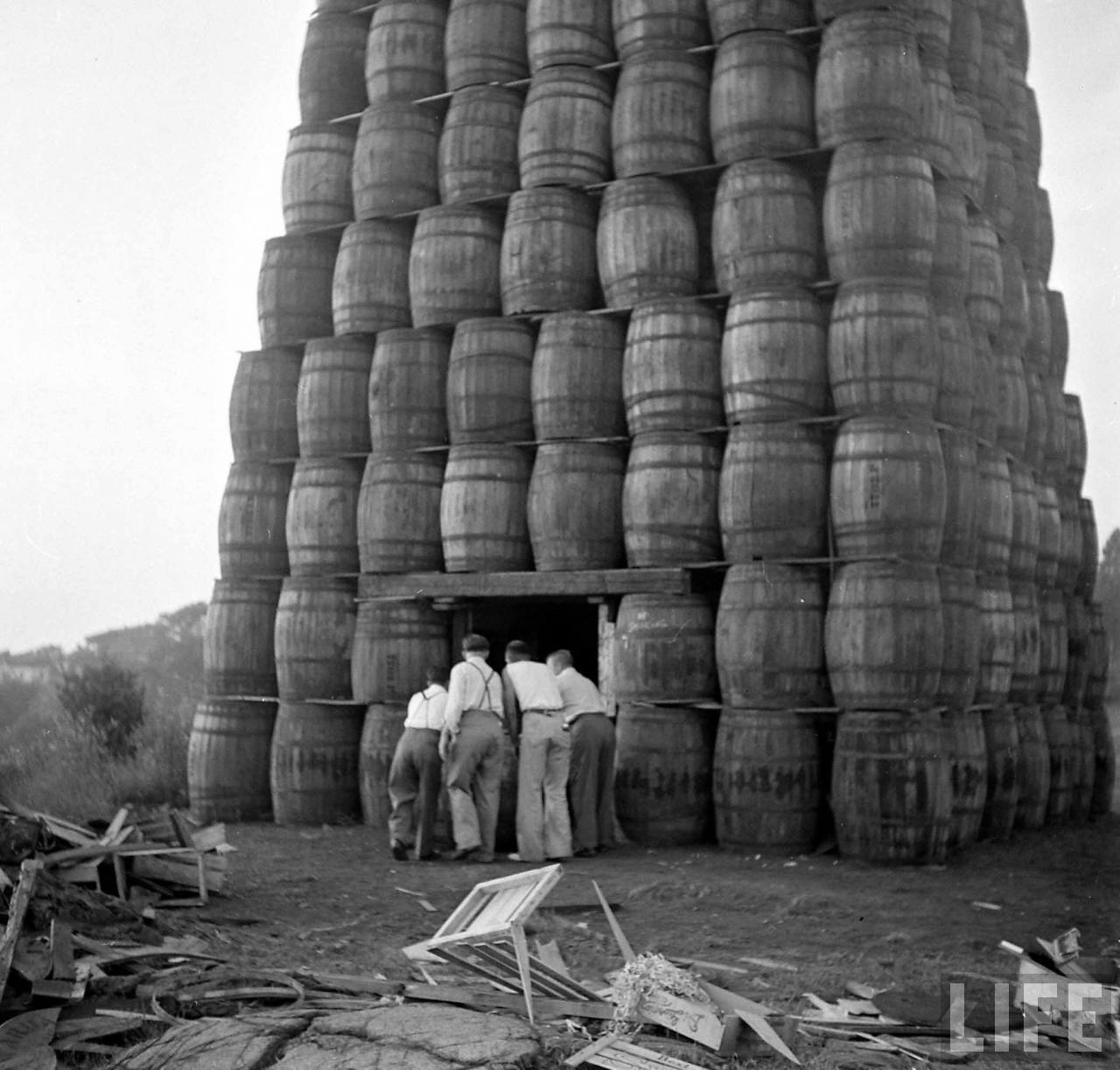

Before there were fireworks, there were bonfires made of Whiskey Barrels!

Can you imagine this today? Someone would be thrown in jail!

That sound you hear is the Devil’s Cut escaping!