It’s not often you hear about the Bark to Glass revolution but, that’s exactly what’s happening in Newport, OR as Rogue Spirits Distillery recently celebrated making its 100th oak barrel. Rogue Spirits and its sister brand Rogue Ale started the Rolling Thunder Barrel Works in 2015 and have been hard at it cutting, bending, toasting, charring and bunging ever since.

The spirit of the Rogue brand, even the name, suggests doing things differently, a desire and a willingness to change the status quo. As the availability of new oak barrels gets tighter and tighter, the folks at Rogue decided to build their own barrels.

Let’s face it, the 2,000 year old art of hand crafting barrels is a dying art. Most barrels today are made in factories with specialists used for each step in the process. That’s not the case with Rolling Thunder Barrel Works; here each barrel is made by hand by a single cooper.

Putting the 2,000 Year Old Art of Barrel Making to Work

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Chances are, you’ve never met a real cooper. Let me introduce you to Nate Linquis, the cooper at Rolling Thunder. Nate is one of the few true practitioners of the barrel making arts. Nate can hand craft a whole barrel from start to finish. The number of coopers that do this in the U.S. today is numbered in the dozens.

With Nate as our guide, we’ll see how what appears to be a few miscellaneous pieces of Oregon White Oak become a barrel for aging craft spirit.

1. Assembling the Staves and Raising Skirts

Staves are the pieces of wood that give a barrel it’s round, bulging shape. Since each barrel is unique, Nate numbers the staves. That way, if he ever needs to take the barrel apart he knows how to put it back together. The practice of numbering staves dates back to the days of the Roman Empire.

Assembling the Staves

Assembling the staves, the first step in barrel making. When all the staves are put together and hooped at one end, the barrel is called a skirt. The French call this part of coopering, mise en rose, or raising the skirt.

Raising the Skirts

2. Toasting and Charring

These two steps may be the most important part of coopering. Barrel aged spirits such as whiskey, get two-thirds of their flavor and most of their color from the wood of the barrel.

Toasting the Barrel

Nate places the skirts over small fires to toast the insides. The fires are started in small metal buckets called cressets. Toasting caramelizes the wood sugars and brings out the flavors. The level of toast varies depending on what flavors he wants to emphasize during aging.

Charring the Barrel with a Blow Torch

Charring is more intense. Nate lights the barrel on fire with a blowtorch and seconds later, the flames are leaping several feet into the air. He lets it burn for about 45 seconds.

Charring – Old Timers Call this “45 Seconds of Hell”

Charring is one of the most dramatic parts of coopering. (This is definitely a crowd pleaser on cooperage tours.) Knowing when to stop is critical. Nate slowly counts down the seconds (not always to 45) and when the char smells right to him, he puts out the fire.

Putting Out the Fire

Nate dampens the flames with water and closes the top with a piece of wood.

Just as toasting adds flavor, charring gives a barrel aged spirits color and that familiar smoky taste. The char also filters out unwanted flavors and impurities.

3. Hooping the Barrel

The metal rings that hold the staves together are called hoops. The length depends on what part of the barrel it’s designed to fit. Hoops that slip over the middle are longer than ones on the end.

Nate hoops the barrels twice. The first time to bend the wood while it’s toasting, the second time to hold the heads in place. He pounds the hoops into place with a cooper’s hammer and a driving iron.

4. Getting A Head

For our coopering ancestors, this was the most difficult piece of the barrel making puzzle. Without heads on both ends, a barrel won’t hold water, beer, spirits or pretty much anything else.

It wasn’t until around 350BC that the Celts of Central Europe figured it out. This was the Iron Age and humans finally had tools that were sharp enough and precise enough to make the cuts that allowed them to put heads on barrels.

This was their breakthrough, a groove cut into the ends of barrels to hold the heads in place. It’s called a croze.

Cutting the Croze into the Barrel

The strange contraption Nate is operating is called a crozer, it cuts the grooves that will hold the barrel heads in place.

Measure Twice, Cut Once

Nate is measuring a croze. He’s got to match the shape of the heads perfectly to the croze or the barrel will leak.

The croze allows the cooper to loosen one end of the barrel, slip in a round piece of wood called the head, and hoop everything back together. Precision is critical. The head and the croze must fit perfectly or the barrel will leak. After shaping the head with a rounding saw, Nate double checks his work.

Double Checking the Croze for a Perfect Fit

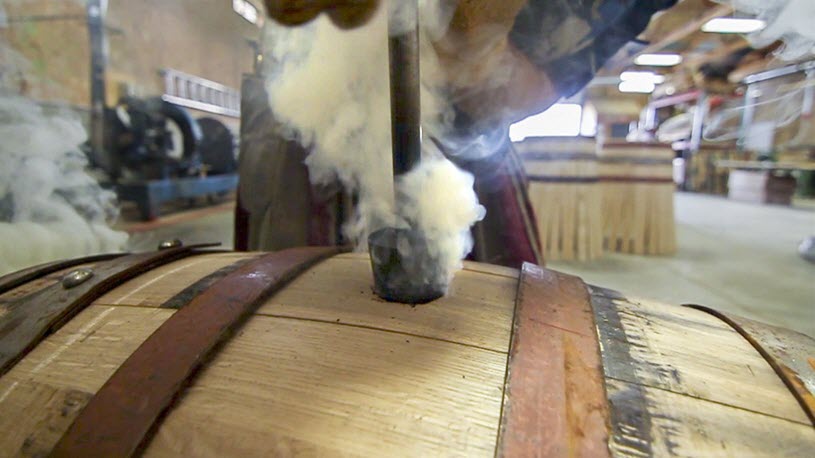

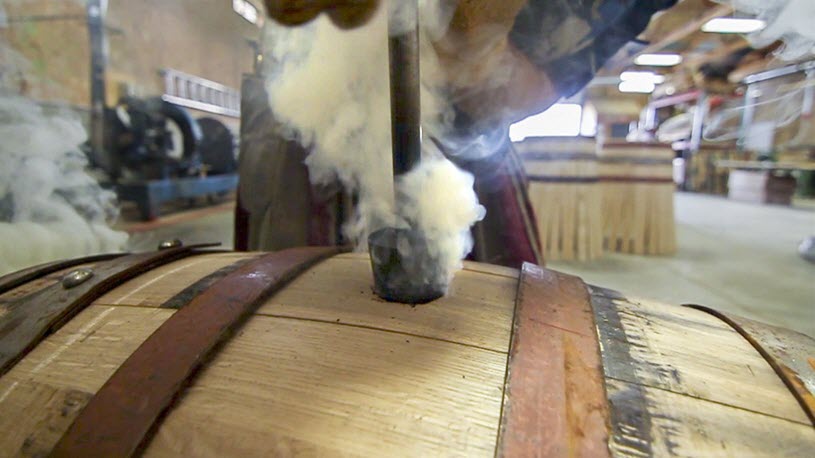

5. The Bunghole

Yes kids, bunghole is a legitimate word in the cooper’s vocabulary. It’s the hole where spirits and beer are poured into the barrel.

Nate drills the hole in the widest stave. Now comes the fun part, sealing the wood around the bunghole with a tool called the bunghole cauterizer.

Feeling squeamish yet?

Heating Up the Cauterizer with a Blow Torch

Cauterizing the Bunghole for a Waterproof Bung Seal

Nate shoves the cauterizer into the bunghole, creating a waterproof seal in the wood surrounding the hole.

After some sanding and other finishing touches, he’s done and another Rolling Thunder Barrel heads off to the ocean aging room to age ales and spirits in the salty air of Yaquina Bay.

One Barrel a Day

Nate hand crafts one barrel per day. A fully operational barrel factory can churn out hundreds of barrels in one shift.

Q: With the odds so clearly stacked against them, why does Rogue making their own barrels using these old fashioned techniques?

A: The answers are DIY and terroir. (What is terroir?)

Do It Yourself

DIY is at the heart of the Rogue Revolution. It’s why they grow their own ingredients at Rogue Farms in Independence and Tygh Valley, Oregon. It’s why they floor malt their barley and rye in small artisan batches at the Farmstead Malt House, and why they bought a used coffee roaster to roast their own malts.

Doing it yourself means they really know what’s going into their beers and spirits. They have an emotional connection to what they grow, and how their crops are crafted into ingredients.

Rolling Thunder Barrel Works is the newest phase of the DIY Revolution and their dedication to reviving heritage, hands-on, artisan ways of making beer and spirits.

Terroir: Wood Is Also An Ingredient

Remember what we said about where barrel aged spirits get their flavor? Wood is as much of an ingredient as anything they put in their beers and spirits. So it was important that the wood in the barrels share the same terroir as the other ingredients.

That’s why they craft their barrels with Oregon White Oak harvested from the Coast Range, just an hour or so from the brewery and distillery in Newport. Rolling Thunder Barrels share the same Oregon terroir as the water, barley, hops and other Rogue Farms crops.

The folks at Rogue Ales and Spirits, say they’re dedicated to saving the terroir of Oregon hops, barley, beer and spirits, one acre and one barrel at a time.

6. Another Completed Barrel Ready for Spirits

Do you want to see the grow your own barrel revolution for yourself? Rolling Thunder Barrel Works is open daily for tours.

Please help to support Distillery Trail. Like us on Facebook and Follow us on Twitter.