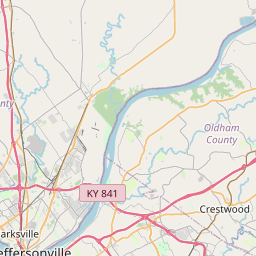

Today, hand crafted copper stills play an integral part in the distilled and craft spirits boom. One of the company’s enjoying that boom is Vendome Copper & Brass Works. Vendome is a family owned business founded by Elmore Sherman at the beginning of the 20th century and is still run by the fourth generation of Sherman’s today. The Vendome brand is known the world round for first class custom, handcrafted products for both large and small makers as well as top-notch installation and service.

Vendome equipment is used to make fine bourbon, rum, gin, vodka and other spirits. We handcraft batch and continuous distillation systems of all sizes. We custom design and engineer each piece of equipment. Our most common systems are designed for low to middle proof whiskey, rum, brandy, or single distillation of GNS, for gin and vodka. All of the systems are capable of producing 190 proof in multiple runs. A vodka column is highly recommended if vodka is the desired product.

In addition to stills, we fabricate all related stainless steel and copper equipment including fermenters, cookers, condensers, coolers, whiskey tanks, bottling tanks, etc.

Distillery Product Line Includes

- Pot Stills

- Column Stills

- Cookers

- Fermentors

- Condensers

- Coolers

- Whiskey Tanks

- Bottling Tanks

- and more…

Still have question? Visit the Vendome Copper & Brass Works FAQ page here.

Do I Need a Batch or Continuous System?

Batch System: A batch system is a heated pot, normally heated with a steam jacket or internal pipe coil. Fermented beer is charged into the pot. It is heated via the steam jacket or coil. The alcohol in the beer is boiled over as vapor and condensed into distillate. The slower and cooler that process is performed, the higher the proof. 5 to 1000 gallons is the best size for batches. A batch system makes all products well. It is best for Brandy, Gin, Whiskey, Rum, Vodka, and similar products.

Continuous System: A continuous system is a vertical column, with 15 to 20 plates, heated with live steam. The fermented beer is fed in the top at a constant rate. The alcohol in the beer is boiled over as vapor and condensed into distillate. The slop is removed at a constant rate from the bottom. The distillate continues to where it gets distilled again in a doubler or thumper.

Can I Get a Price Estimate?

Yes! please visit our Pricing Request form here and we will get back to you.

What is the Approximate Time from Order to Delivery?

Our delivery time varies but a good rule of thumb is seven to 12 months, sometimes more, sometimes less. If you have a service issue for an existing system, we’ll work with you to get you what you need as soon as possible. We understand this is not a hobby but your business.

Call Us Now at 502.587.1930

We’ll Help to Craft Your Dream!

Email: Office@VendomeCopper.com

Click Here to Download Vendome Copper & Brass Works

Distillation System Brochures