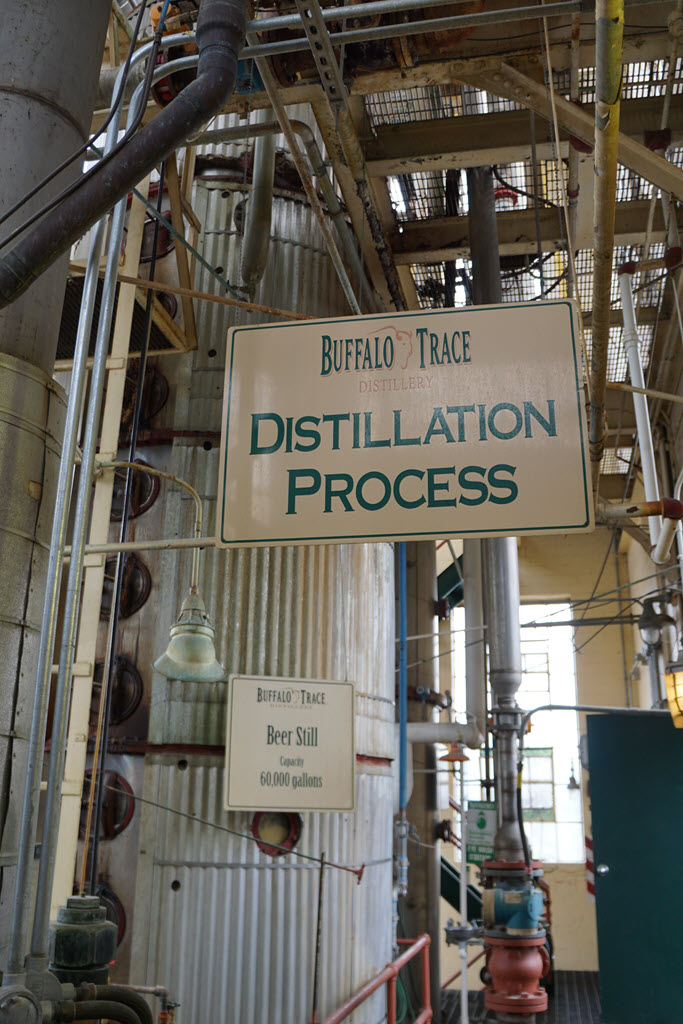

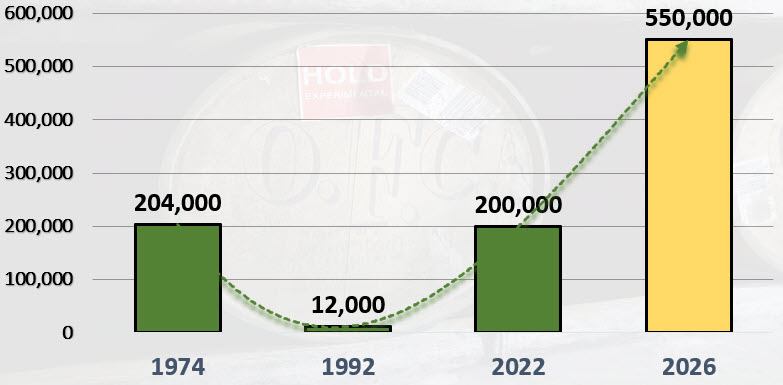

Commercial distilling has been taking place at the Buffalo Trace Distillery site in Frankfort, Kentucky since the 1800s. As recently as 1992 during the downturn in brown spirits the distillery was making as few as 12,000 barrels of whiskey per year and the staff was down to a mere 50 employees. Fast forward to the 2000s and those fortunes have changed — dramatically. They are now making more than 200,000 barrels a year and that number is now set to more than double after this latest ribbon cutting celebrating the commissioning of their new column still.

Buffalo Trace Bourbon Journey Goes Boom to Gloom to Ba-Boom

-

Save

As bourbon whiskeys popularity and premiumization has soared over the last decade phrases like bourbon shortage, limited-supply, and the dreaded ‘allocated distribution’ have taken over the distilled spirits industry lexicon. There is likely no other distillery more often connected to the phrase ‘allocated’ than Buffalo Trace.

Back in 2013 the folks at Buffalo Trace Distillery recognized they had a problem – they could not keep up with current demand let alone future demand. It was about that time they started working on a long-term plan. What came out of that realization was the beginning of a $1.2 billion 10+ year investment plan. Unlike some spirits like vodka or gin that can be distilled, bottled and shipped almost in real-time, bourbon takes time, lots of time to make and mature.

To help put this in perspective, let’s consider a couple of Buffalo Trace’s fan favorites like the elusive 23-Year-Old Pappy Van Winkle Kentucky Straight Bourbon Whiskey or the 18-Year-Old Sazerac Kentucky Straight Rye Whiskey. Unlike the country furniture maker with the roadside sign that reads “Antique Tables Made Daily” making and releasing high quality bourbon and rye whiskies in a few days is simply not possible. Buffalo Trace is one of the few companies that has a regular release of a 23-year-old bourbon whiskey. Just think, the bourbon whiskey that they are making in 2023 won’t hit the 23-year-old mark and be bottled for distribution until 2046. Forecasting how many bottles you’ll sell in 2046 falls somewhere between great planning and gazing into a crystal ball.

In 2016, Buffalo Trace announced it would be investing $200 million to expand production at its National Historic Landmark distillery. At the time, details said the investment would have several phases covering seven years. In the meantime, Bourbon sales continued to grow in the United States by 5% annually and by mid-2018 the distillery announced its investment plans grew to $1.2 billion (that’s billion with a ‘B’ as in Bourbon) and the scope expanded to cover the next decade. The investment included acquiring more land, expanded production facilities that would include milling, cooking, fermenting, cooling, distilling, water purification, distillers spent grain (DSG) processing, warehousing, bottling and expanded tourism facilities.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

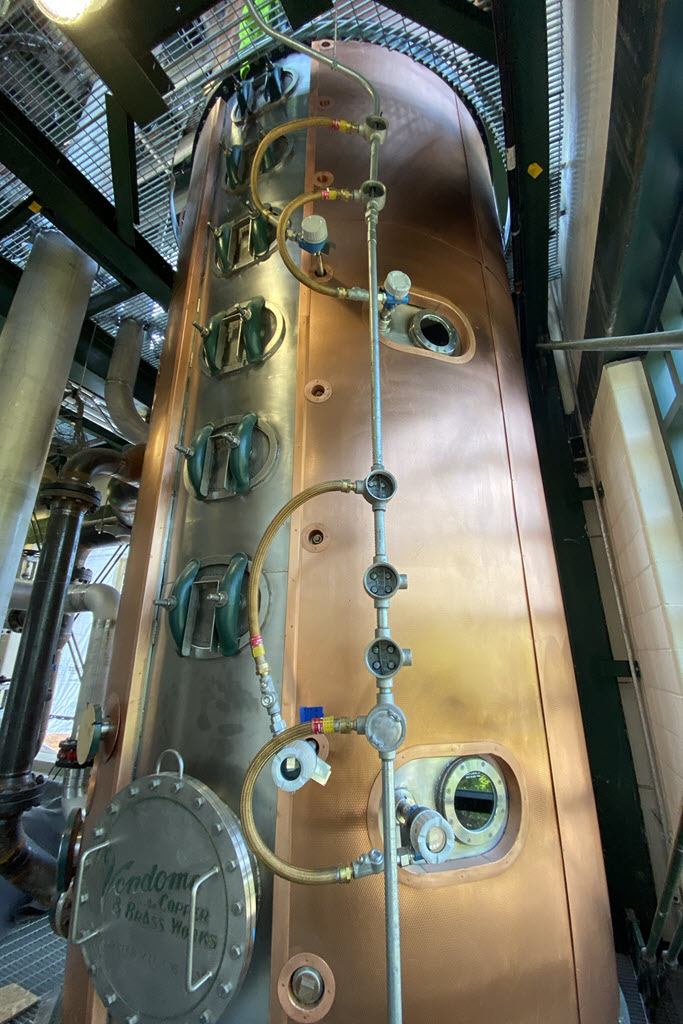

Buffalo Trace Cuts the Ribbon on Massive New Still, Doubling Whiskey Capacity

After nearly a decade of planning the doubling of distillation capacity is now a reality as Buffalo Trace Distillery officially commissioned their new still. Whether you call it science or superstition Buffalo Trace took their existing 84” wide by 40’ tall Vendome Copper & Brass Works column still and duplicated it. You see, the new column is a mirror image of the 67-year-old beer still that was put into production in 1956. As Thermaltech Engineering Principle Kyle Leahman pointed out at the ribbon cutting, the still is basically the same except the old one had about 10 to 15 sensors vs. the new one that has 100+ sensors to monitor its progress during distillation.

-

Save

When Will the Buffalo Trace Bourbon Shortage End?

Today, Buffalo Trace is operating their stills 24×7 and is now on their way to making 550,000 barrels of whiskey per year. Keep in mind that the bourbon made today will need to age in a rickhouse for 4+ years but there is light at the end of the rickhouse. Stay tuned!

-

Save

Buffalo Trace Distillery is an American family-owned company based in Frankfort, Franklin County, Kentucky. The distillery’s rich tradition dates back to 1773 and includes such legends as E.H. Taylor, Jr., George T. Stagg, Albert B. Blanton, Orville Schupp, and Elmer T. Lee. Buffalo Trace Distillery is a fully operational distillery producing bourbon, rye and vodka on site and is a National Historic Landmark as well as is listed on the National Register of Historic Places.

Related Stories

- The Complete Buffalo Trace Distillery Timeline – 1773 to Today

- Buffalo Trace Distillery Celebrates the Filling of its 7 Millionth Barrel – Honors Family Tradition [Video]

- Sazerac Co. Announces $600 Million Expansion – Largest Distilled Spirits-Related Investment in Kentucky’s History

- Buffalo Trace Distillery Production up 50% as $1.2 Billion Expansion Continues – Capacity to Double to 2,000+ Barrels/Day by Year End

Learn more about Buffalo Trace Distillery.

View all Frankfort Distilleries.

View all Kentucky Distilleries.

View all U.S. Distilleries.

Most Popular

- Four Roses Celebrates 20 Years of Single Barrels…

- Rare Opportunity: Successful Kentucky Distillery and…

- Michter’s Distillery 20-Year-Old Bourbon Returns for…

- Balance Distilling Co. Revives 1869 Weller Brand…

- Four Branches Bourbon Veteran Founders Change Their…

- Maker’s Mark Distillery Announces the 9th Master…

- Buffalo Trace Distillery Releases its Full 2024…

- Southern Distilling Company Launches Limited-Release…

- Federal Judge Rules Ban on Home-Distilling is…

- A Day on the Trail: Startup Potter Jane Distilling…

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.