There’s no doubt, the craft spirit that is inside the bottle is the most important part of what you do. If a consumer likes what’s in the bottle, it will keep them coming back, if they don’t well, you’re toast. But, what does it take to get a consumer to try or purchase your product? A lot of that starts with your brand – it’s your story, it’s your look, it’s your feel, it’s your baby.

Whether it’s in a retail store, a tasting at a farmers market, a local bar or dozens of other places the first thing people are going to see is your bottle.

It’s often said of packaging that you have to grab a consumer’s attention in 10 seconds or less.

Today we are going to explore the importance of the bottle you choose to place your craft spirits in. There are lots of choices from straight off the shelf, semi-custom all the way up to totally custom. When you are first starting out, it’s easy to think we don’t have the money now so let’s go with something off the shelf. That can, and does work but, before you go down that road, explore your options then decide.

Stay Informed: Sign up here for our Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Here’s a quick lesson in “Glass” from the book Branding: Distilled, A Guide to Package Design for Craft Spirits by Cynthia Sterling. Cynthia is the principle and creative director at Sterling Creativeworks. If you like this lesson, click here to pick up your own copy of her book, Branding Distilled.

Stock vs. Custom Bottles

The bottle you choose for your package has a big impact on the first impression and overall quality communication made by your brand. It sets the expectations for your product style and quality. A heavy bottle with quality elements such as a crest or embossing will communicate that care and effort was put into making the product, just as effort was put into the fine characteristics of the bottle. Although the cost of a high-quality bottle may feel like a stretch for a startup budget, using the right glass from the beginning is important. Modifying the label size and ordering different materials later will cost more in the long run. And, not having the right bottle will undermine your brand’s image during the critical “first impression” stage of launch.

Stock Bottles

There are many stock bottle options available. European glass suppliers offer very creative options and they are continually developing new bottles and carafes. It is not difficult to find stock bottles for quantities as low as 100 cases worth. European bottles come in bulk on pallets, so shipping cartons and gift boxes must be purchased separately.

Semi-Custom Bottles

Glass specialists travel to China to create and import their own designs at affordable prices for semi-custom shapes. Chinese bottle quality varies, and it’s important to work with a proven supplier to ensure American standards are met. Because production costs are lower in China there are more opportunities to modify bottle elements and obtain a unique design.

Custom Bottles

A custom bottle shape designed and produced specifically for your brand conveys the highest quality message because it communicates a larger investment in the brand. There are some limitations to creating a custom bottle beside the one-time investment in the development of the bottle molds: the minimum run size is at least 1,000 cases and may be as high as 3,000 cases.

The cost of most custom bottles will be 40% higher for smaller production runs, but, at quantities above 5,000 cases pricing begins to be within 20% of the cost of a semi-standard bottle at the same weight.

Besides quantity and price, the weight of the glass is a factor. Standard bottles weight 500 grams (1.1 lbs), whereas thick-based bottles weigh around 800 grams (1.8 lbs). Not all factories will make these heavier weight bottles or do it well. The shape of the bottle will also affect the price. Square and unusual shapes are more difficult to make and the price will reflect this.

Sustainability of Glass: Recycled Bottles

All bottles are made from recycled glass because it lowers the amount of raw material needed and reduces the amount of energy required to melt the raw materials: soda ash, sand and limestone. Recycled content can range from 25% to 95%, but most fall in the range of 40% recycled content. Because glass does not degrade with multiple recycling, it’s a highly sustainable material.

Weight and the Carbon Footprint

Bottles have become lighter in weight over the past 30 years as the quality of forming equipment and inspection machines has improved. Bottles weighing 420 grams (0.925 lbs) can now easily be manufactured, whereas the heaviest ones weigh 1.2 kg (2.64 lbs). Although less environmentally friendly, heavy bottles are popular because the luxury market wants the variety and cult appeal.

However, concerns about wastefulness are valid and many specialty shapes are being made at lighter weights, allowing a craft look with a lower carbon footprint. The benefits of lighter bottles are not only lower production costs and lower emission of noxious gasses during melting, but also the final product will weigh less and take up less room during transportation.

Each brand owner must balance the cost and sustainability differences between lighter and heavier bottles against the luxury appeal of heavier glass and make an informed decision that fits their branding and sustainability goals.

Quality Perception Begins with First Impressions

Glass bottles are the perfect vessel for keeping a liquid safe and unaffected by oxygen, and do not extract flavors or allow any leaching of outside elements. But mostly, a bottle can be beautifully shaped—which is key to a successful and lasting impression. It sets the tone for your brand personality, conveys the quality of your product, and becomes a key part of brand recognition, allowing consumers to spot and recognize your brand on a shelf or back bar quickly.

Get to Know the Parts of a Craft Spirits Bottle

A. Through Bore – This refers to the minimum neck diameter for ease in bottling. A fill tube must typically be at least 1mm narrower than the through bore. For example, if a through bore is 16.5 mm, then the fill tube is recommended to be 15.5 mm. Normal filling tubes are 15 mm or larger.B. Bore – This term refers to the dimension at the very top opening of the bottle and tells the bottler what size cork should be used for the best seal. Standard bore for the U.S. is 18.5 mm (0.728 inch). Many larger-necked spirits bottles use 21.5 mm (0.846 inch) or larger. The length of the bore inside of the neck is important for ensuring proper cork sealing.

C. Bottle Ring – Sometimes called the bead, this is the flared top section of the bottle. A seam on the lower edge of the ring shows where this part of the mold is joined to the body mold. The bottle ring can be interchanged with a compatible body mold.

D. Bottle Neck – This part of the bottle takes on a difficult task when air is blown into the bottle. It must be straight inside and out, creating a controlled cylinder for the cork to fit in. A thin neck takes a smaller diameter cork, while a fat neck will require a larger cork.

E. Shoulder – The widest part at the top of the body, just below the neck. If embossing is used, it is usually applied here because this area has no bottle-to-bottle contact point when bottles stand side-by-side.

F. Label Panel – The bottle blueprint shows the location and size of the label panel. Designers should use this reference to ensure the label fits on this flat area.

G. Punt – This pushed-up area is a traditional addition to the bottle. It has no real use in current glass making, but some consider a deep punt to be an indication of quality. The punt can add height to a bottle by taking up volume in the base, and can be customized.

H. Base – The bottom of the bottle has a base plate where the base attaches to the body mold. This area can be customized.

These are just a few sample bottle images from the book Branding Distilled: A Guide to Package Design for Craft Spirits. You can pick up your own copy here to see them all.

Distillery: House Spirits Distillery, Designer: Sandstrom Partners

Distillery: Double V Distillery, Designer: Sasquatch Agency

Distillery: Woodinville Whiskey Co., Designer: David Cole Creative

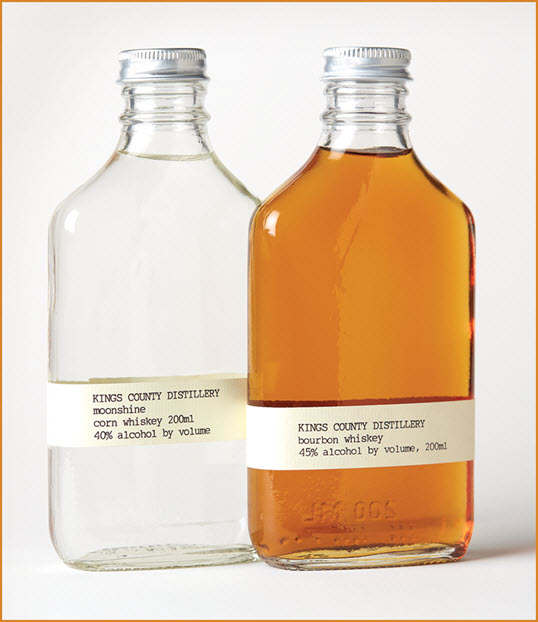

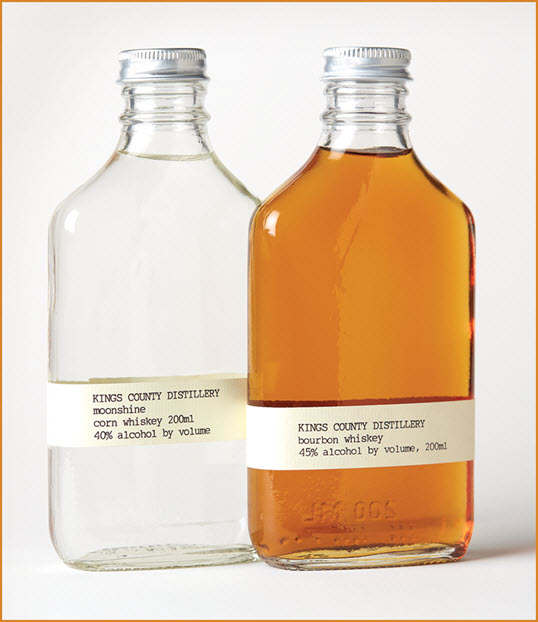

Distillery: Kings County Distillery, Designer: In-house

Get to Know the Parts of a Craft Spirits Bottle