You often hear you can’t teach an old dog new tricks. Well on the flip side when your entire distillery operation was a corn field just five years ago, nothing is old and literally everything is new. Such is the case at Bardstown Bourbon Company located in the heart of the Bourbon Capital of the World, Bardstown, Kentucky.

This distillery field of dreams has grown into one of the premier distillery and tour destinations not just in Kentucky but in the entire country. Bardstown Bourbon’s path is different than most new distilleries. Instead of building a distillery and launching their own brands, Bardstown Bourbon brands only make up 15% of distillation while the remainder is for their distillery partner brands. Many of those ‘other’ brands are well known national brands like Belle Meade, Hirsch, Calumet, Jefferson’s Reserve, High West and James E. Pepper while others are up and coming and because of aging may not be known to the world for a few more years.

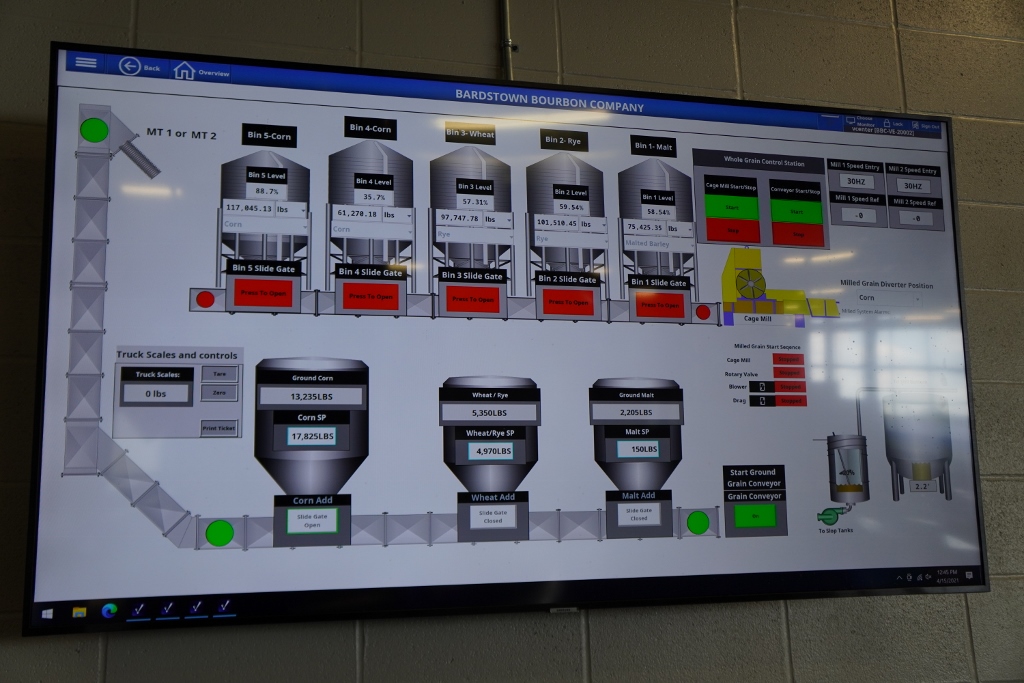

To help put what they are doing in perspective they are running not just a handful but 55 different mash bills for 32 customers. Stop and think about that for a moment. That’s a lot of bourbon, rye and whiskey mash bills to run in multiple distilleries let alone all under one roof.

The Journey from 1.5 to 7 Million Proof Gallons

We recently had the opportunity to spend a Day on the Trail at Bardstown Bourbon Company to get an inside look at the distillery and new bottling facility with Chief Operating Officer John Hargrove.

The modular design of the distillery has allowed for multiple expansions over its short life span.

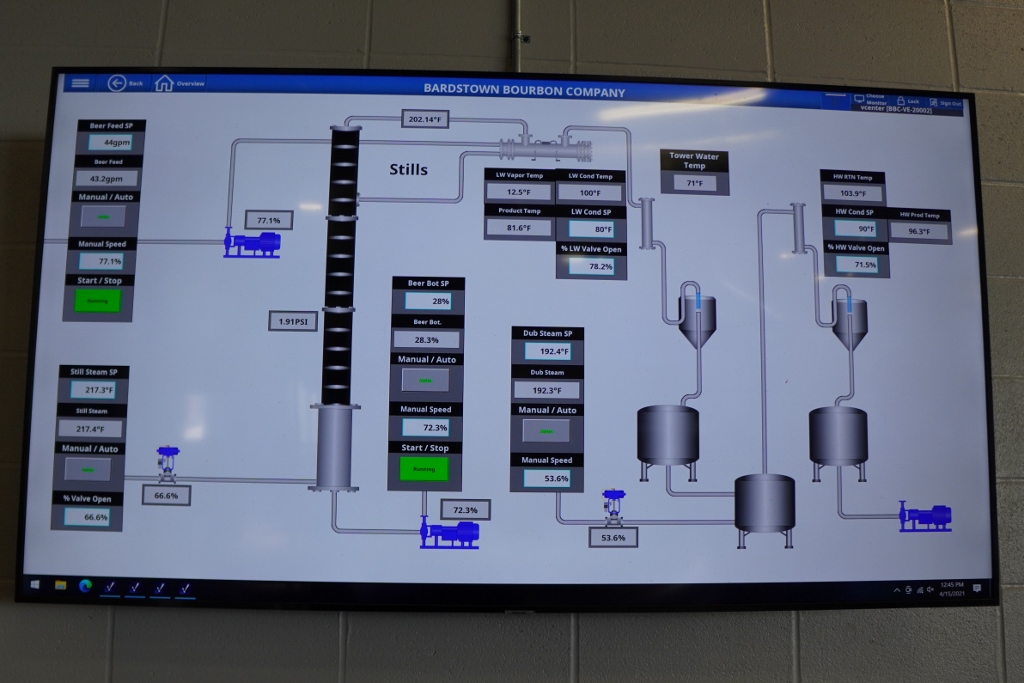

“In 2016 we started out at 1.5 million proof gallon capacity,” explained Hargrove. “In 2017 we doubled to 3 million proof gallons. In 2018 we doubled again to 6 million proof gallons. In 2019 we went through some efficiency upgrades and last year we produced 7.3 million proof gallons so a little over 115,000 barrels aging. We have 32 different customers in our Collaborative Distilling Program with 50 plus different mash bills.”

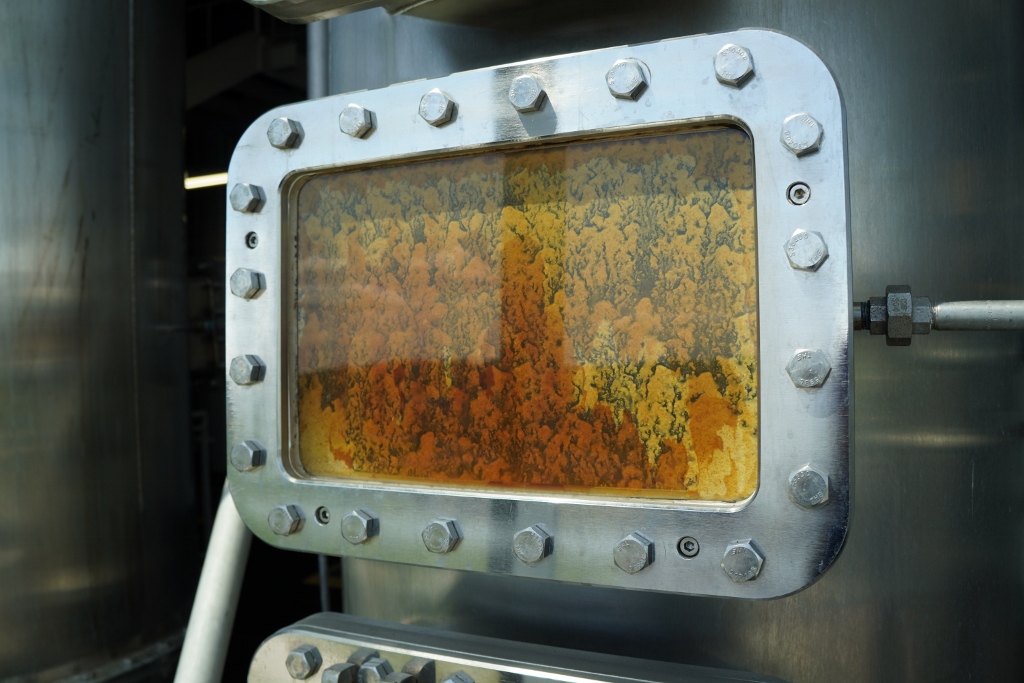

They run a combination of sweet and sour mash distillate throughout the week depending on the customer.

“We do two, three, four and five grain bourbons,” said Hargrove. “Wheated whiskey, rye whiskey, grain in, American single malt. A little bit of everything. The grains can vary by customer. We’ve done Russian wheat, heirloom corn – red, white, blue, black, a little bit of everything. Our minimum order is a three hundred barrel order. We keep the stills running. Our ‘Ignition’ system feeds us with over 400 data points sent back from the system. We can see what’s going on through every step in the process. We run 24×7, we shut down for two weeks in the summer and one day for Christmas.”

Bardstown Bourbon Putting Final Touches on 55,000 Square Foot Bottling Line Facility

Now that the distillery has four to five years of matured bourbon, rye and whiskey in their rick houses its time for bottling some of that liquid gold. And just like their twin 50 foot tall column stills are big their new soon to open bottling facility is big as well.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

This 55,000 square foot state-of-the-art facility goes well beyond a standard bottling house and is created to meet or exceed ISO 9000 food safety certification. The facility’s design is a continuation of BBC’s modern look and feel created in partnership with architectural firm Joseph & Joseph + Bravura Architects and developed by Buzick Construction.

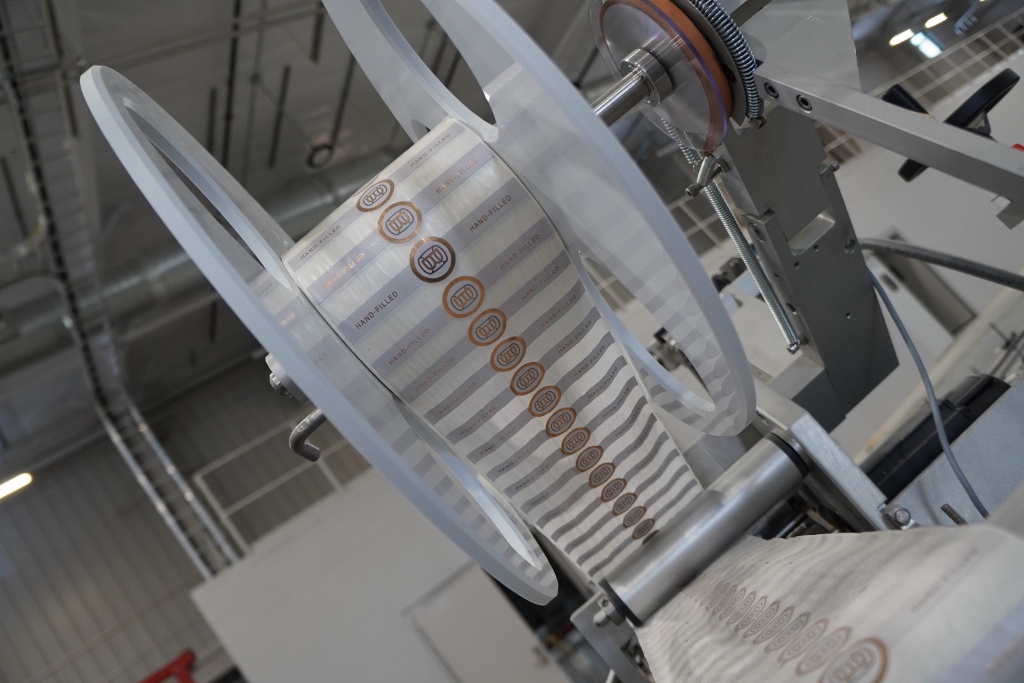

The new bottling line is designed to provide the highest level of quality and safety control, but also the flexibility to customize all specifications in accordance with customer guidelines. It includes a logistics lab, comprehensive testing abilities, component and label flexibility, expert sourcing and an on-site blending lab.

“The bottling facility is the natural next step in our evolution,” said Bardstown Bourbon Company CEO Mark Erwin. “Currently, our brands and our collaborative distilling partners are bottled by an offsite third party. We’re excited to close the circle and enable a true grain-to-glass process all in our own space.”

“It will currently start out with a one shift operation,” said Hargrove. “It will create 25 new jobs. It will be operated by Justin Willett our Executive Director of Manufacturing and Operations and Johnnie Colwell Operations Manager. With a one shift operation we’ll be able to do 815,000 4.5 liter six packs per year. And then we can expand going into more shifts if we need to based off demand. We also built very modular to build out both on the warehousing and processing side and the bottling line. We’ll be processing all of the spirits that we make for ourselves and our distillation partners but we do have capacity to co-pack for new partners as well. This makes us a one stop shop from brand ideation to getting your bottle out into the market.”

“Our new facility will be food safety certified with the ISO 9000. Employees will have to walk in and go through a cleaning room before going out onto the production floor.”

“We’ll have two lines, line one and two. One is a specialty low volume line from single barrel to 20 to 30 barrel dumps. The other one will be large batch 8,000 gallon batches. It’s very versatile. Just like on the distillery side we have 32 brands currently and we’ll have even more in bottling. We’ll have cappers, corkers, tax stamp applicators, quad block filler capper-corker, label machines, sleeves, and a lot of additional cool things.”

“From start to finish from the time we broke ground to when we’ll be running our first bottling line we’ll be at 363 days. For a project that normally takes 16-18 months we’ll be right at 12 months.”

“Our facility will be food safety certified. We want to lead the way in the spirits industry and lead toward the food manufacturing facility. On a global scale if a customer comes to Bardstown Bourbon and asks ‘How do I know if my product is going to be safe with you?’ not only can we show you the audits and the certifications, your allowed to come on property and see how transparent we are with you. You can look at production reports with us. You can go into our lab and look at our quantitative and qualitative analysis.”

And just like the distillery the bottling line will soon be open for tours.

“In the future specialty tours will come through up top (on the second floor) overlooking the entire operation to be keep visitors off the production floor.”

“All employees have already been hired and May 12 will be out first bottling run.”

Bardstown Bourbon Company distillery is currently open for tours and offers the only full-service restaurant located within a distillery on the world famous Kentucky Bourbon Trail.

Learn more about Bardstown Bourbon Company.

View all Kentucky Distilleries.

View all Bardstown Distilleries.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.