Ah, a visit to a distillery – the scents, the sounds, the taste. Just close your eyes as you walk in the door and you know exactly where you are as your senses take over. You can smell the raw grains, the magical fermentation process and the Angel’s Share as the spirits silently exit the maturing white oak barrels. You can hear the steam as it rolls up the still, the trickle of the spirits as they flow through the spirit safe. You know exactly where you are. Then of course there’s the best part of a distillery visit, the tasting. Sometimes it’s the white dog off the still, other times it’s the finished product as you wrap up a visit to the distillery. A little bit of heaven on earth.

Grand opening ribbon cutting. From left to right: L to R: Bill McDermond – Co-Founder Sagamore Spirit, Dutch Ruppersberger – U.S. Rep for MD’s 2nd Congressional District, Catherine Pugh – Baltimore City Mayor, Boyd Rutherford – Maryland Lt. Governor, Brian Treacy – President Sagamore Spirit, Tom Geddes – CEO Plank Industries and Marc Weller – President Sagamore Development.

Grand opening ribbon cutting. From left to right: L to R: Bill McDermond – Co-Founder Sagamore Spirit, Dutch Ruppersberger – U.S. Rep for MD’s 2nd Congressional District, Catherine Pugh – Baltimore City Mayor, Boyd Rutherford – Maryland Lt. Governor, Brian Treacy – President Sagamore Spirit, Tom Geddes – CEO Plank Industries and Marc Weller – President Sagamore Development.

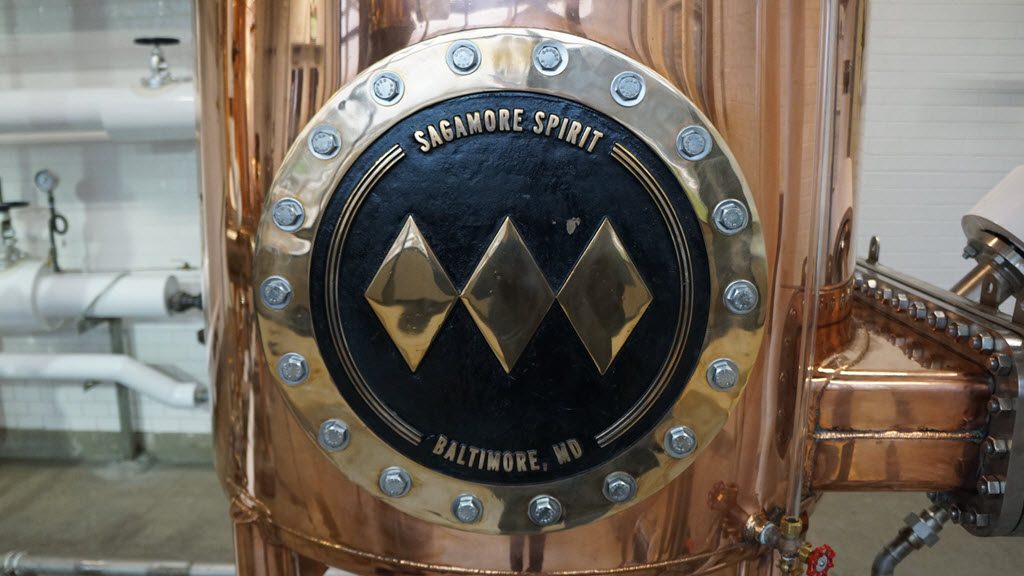

This is the experience you will find this week at the grand opening of Sagamore Spirit Distillery. When you walk in the door, there are antique whiskey bottles hanging in the air, walls covered with weathered wood, images of thoroughbred horses running across lush green pastures, talk of naturally filtered limestone water and of course whiskey, rye whiskey. All this makes you feel as though you are in the bluegrass state of Kentucky but check your GPS, you are in Port Covington, Maryland on the banks of the Patapsco River near the Chesapeake Bay. You’ve just arrived at DSP–MD–20019, the new Sagamore Spirit Distillery.

Sagamore Spirit Distillery – Founded in 2012

Sagamore Spirit Distillery is the brainchild of Co-Founders Kevin Plank and Bill McDermond. Kevin Plank is the Founder, CEO and Chairman of apparel maker Under Armour. McDermond worked as an executive at Under Armour until he left the company in 2009. The two long-time friends and entrepreneurs decided they wanted to get in the whiskey business together. After doing some research they discovered that in the early 1900s, their home state of Maryland was once the third leading distiller of whiskey in the U.S. behind Kentucky and Pennsylvania, and at one point led the nation in rye whiskey production. A little amendment in U.S. law known as Prohibition was the beginning of the end of distillation in Maryland. When the US entered World War II, 100% of the distilleries were turned into ethanol plants to support the war effort. After the war, very few of those ethanol plants converted back to rye whiskey distilleries and the rye whiskey industry in Maryland pretty much disappeared. Now, Sagamore Spirit Distillery wants to help return Maryland to its rye whiskey production heritage.

The name Sagamore comes from Sagamore Farm, a 530 acre thoroughbred horse breeding farm in Reisterstown, MD that Plank purchased in 2007. As luck would have it, there’s a springhouse on the farm that sits atop a natural limestone aquifer. It’s that water that is used to blend all of Sagamore Spirit rye whiskey down to bottling proof. You can now find that limestone water sitting inside a 120′ tall water tower after making the 22 mile ride from the farm to the distillery. That water will be used during the entire distillation process inside the new distillery. By the way, that 1909 you see embossed on every bottle of Sagamore Spirit, that’s the year the springhouse was built.

Springhouse at Sagamore Farm. Built 1909.

Springhouse at Sagamore Farm. Built 1909.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Building a Distillery

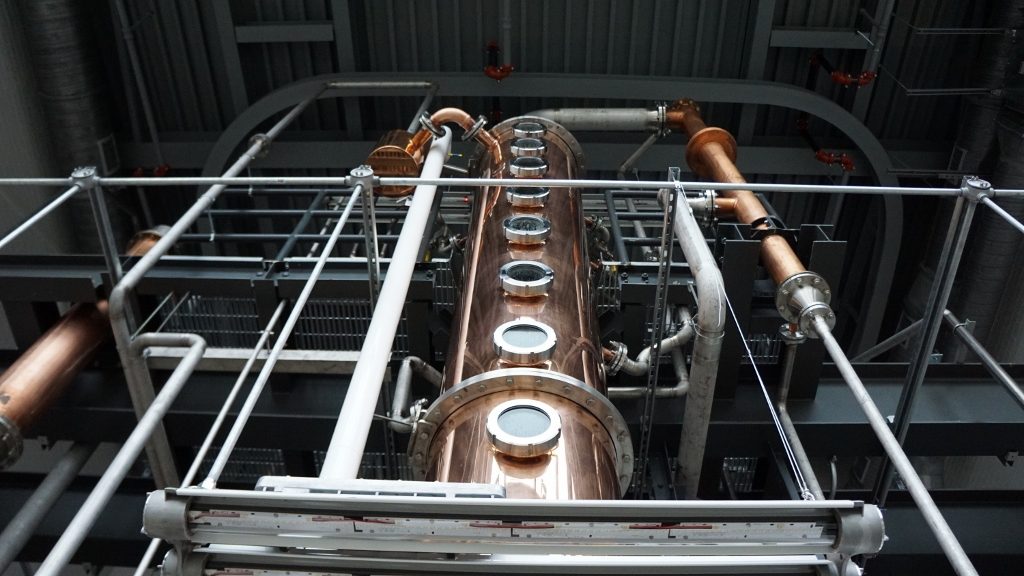

A 40′ Tall Mirror Finish Copper Column Still

When you visit the distillery you will see that everything is top notch from the ground up. Sagamore Spirit enlisted the help of industry veteran Larry Ebersold, the former master distiller at Seagram’s (now known as MGP) in Lawrenceburg, Indiana to design the distillery. Before you enter the distillery building you’ll see a large column still shining through the glass. Once you get inside you’ll discover the reason the still stands out so much is that is has a mirror finish, a feature Sagamore says is the “worlds’ only 40-foot mirrored finished copper column still.” If you like copper you’ll love this baby. It’s a 40′ tall, 24″ diameter mirror finished copper column still with 19 plates manufactured by Vendome Copper & Brass Works. The 3,700 lb. still took a dozen craftsmen over 1,200 hours to build. (I’ll bet 25% of that was just to buff out the mirror finish.)

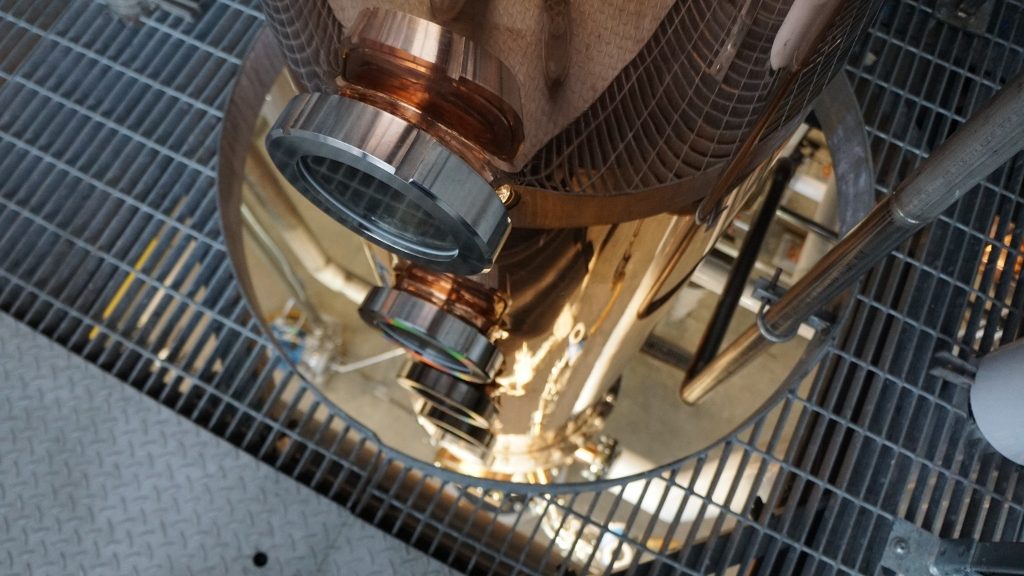

The rest of the distillation equipment includes a 6,000 mash cooker, nine 6,500 gallon fermentation tanks and an 8,000 gallon beer well. As the spirits make their way through the distillation process they’ll travel through three spirit safes with a custom three diamond Sagamore logo on each one. Take a close look at the photos below and you’ll see what looks like another Spirit Safe in the shape of a house. What looks like another Spirit Safe in the bottling building is actually a Water Safe. Look close and you’ll see an image of the 1909 Sagamore Farm Springhouse etched into the glass. The water that bubbles through this copper box is the water that comes from the farm and will end up in every bottle.

As you walk through the distillery you’ll discover another mirror finished 250 gallon copper pot still. Many craft spirits distillers would be quite happy with this as a standalone operation. For Sagamore Spirit Distillery, this is their research and development operation that will be used for seasonal releases and new spirit expressions. Take a look at the photos below and you’ll see that the mirrored copper finish goes all the way from the legs of this still to the top of the column. (Someone will be doing a lot of polishing around this place!)

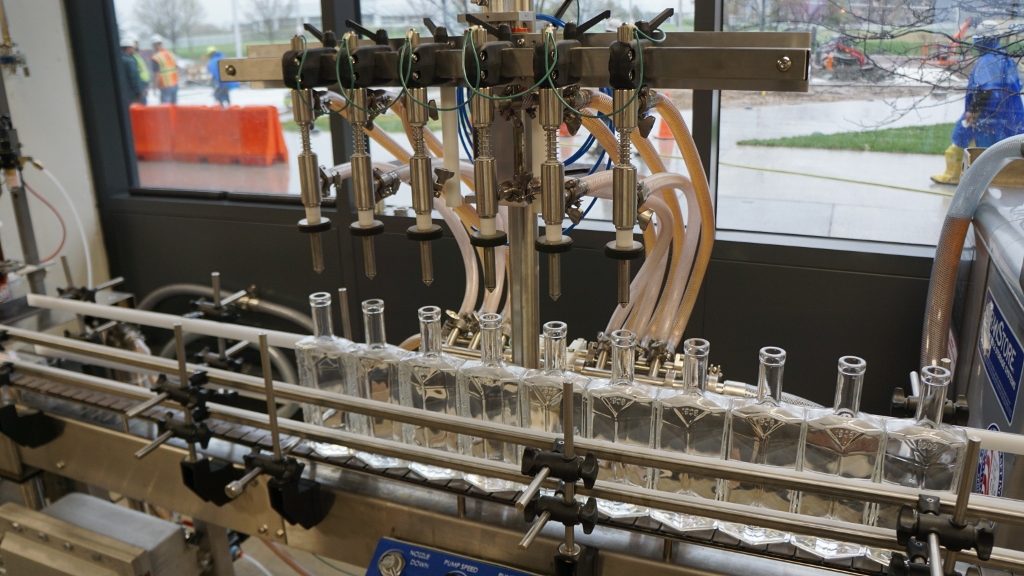

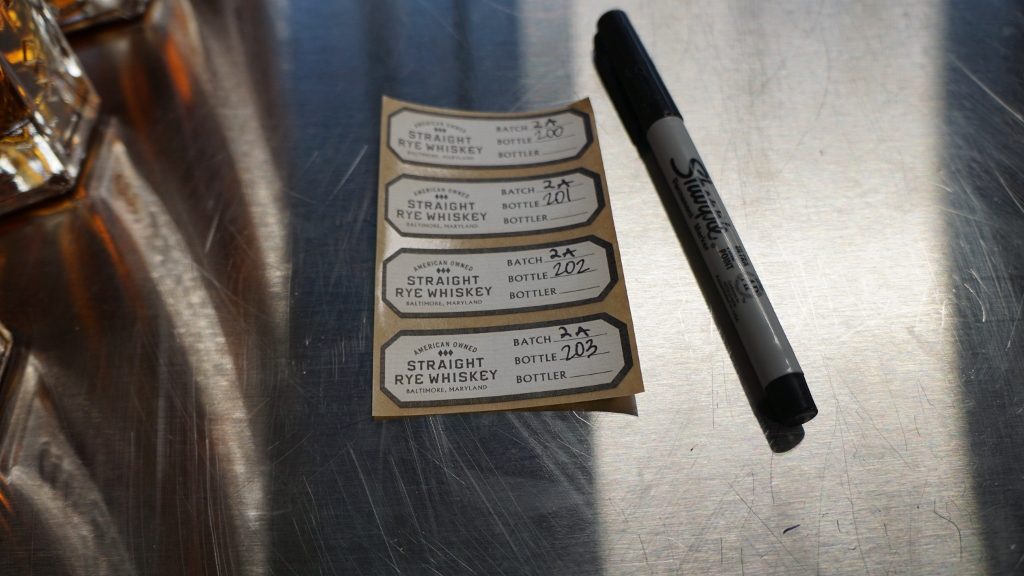

The processing building holds Sagamore’s bottling line, barrel filler, and barrel dump trough. The bottling line required a custom labeler to accommodate Sagamore’s unique hexagonal shaped bottle. Ten 1,000-gallon proofing and gauging tanks reside on the second floor. Together, the distillery and processing buildings house over two miles of process piping.

Sagamore Spirit Distillery is now operational. Visitors can stop by for a tour and see how rye whiskey is once again being made on Baltimore’s waterfront. The distillery is open daily for tours and tastings from 10AM to 5PM. The visitor center is open from 9:30 AM to 6:30 PM.

Related Links

Ayers Saint Gross

DTM Packaging

Sagamore Spirit Distillery

Vendome Copper & Brass Works

Sagamore Spirit Distillery Photo Gallery

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.