Construction continues at Buffalo Trace Distillery in Frankfort, Kentucky. The distillery is currently in the midst of a 10 year $1.2 Billion (yes, with a B) expansion so one day you too can walk into any liquor store and pick up your own bottle of Buffalo Trace Bourbon, Blanton’s or Pappy Van Winkle. Well, we added that last part but a person can hope right?

1+ Million Barrels of Whiskey Aging at Buffalo Trace Distillery

One part of that $1.2 Billion investment includes putting up new barrel warehouses on their adjacent 292-acre farm. Currently they are building massive 58,800 barrel warehouses with a completion rate of one new warehouse every 120 days. Since spring 2018 they’ve built and filled warehouses AA through JJ. Simple math tells us that’s 588,000 new barrels of whiskey or approximately 141,120,000 bottles of whiskey depending on how thirsty the Angels are in the various floors of the new warehouses. All told, with the completion of 10 new barrel warehouses puts the entire Buffalo Trace on-site barrel inventory of over one million aging whiskey barrels.

The new warehouses are seven stories tall, metal clad with insulation. The floors are wooden. Unlike most distilleries, Buffalo Trace heats its warehouses, starting with steam heat Col., E.H. Taylor, Jr. brought to the warehouses he built in the late 1800s, and still used today on Buffalo Trace’s main campus.

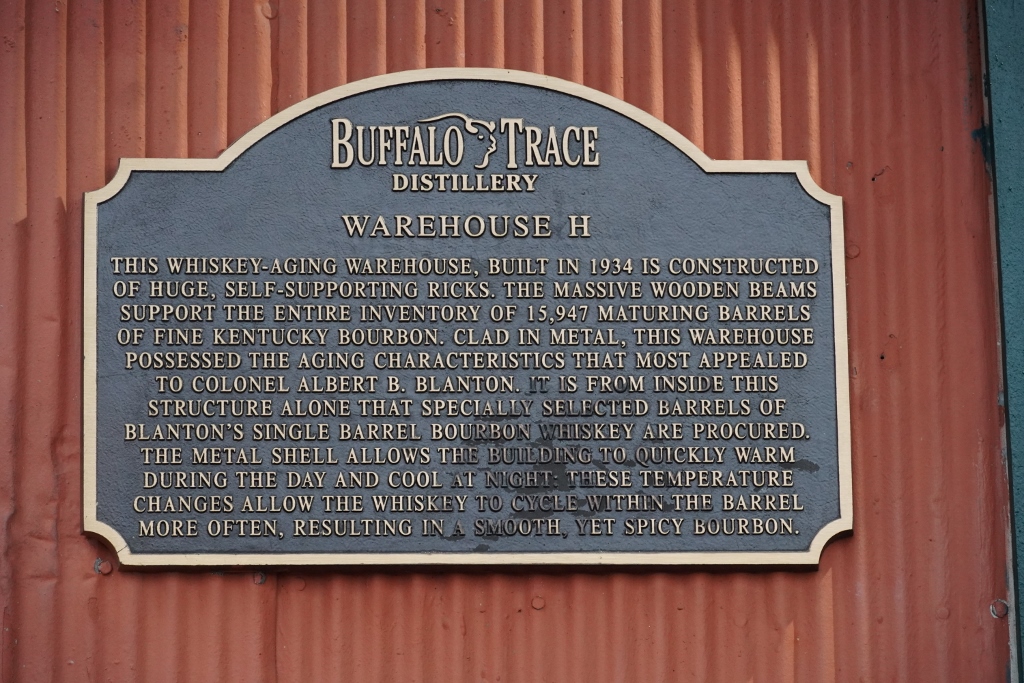

And for those doubters out there steam heating is actually happening. We took this video of the infamous Warehouse H during a chilly December day. Warehouse H is a metal clad steam heated warehouse that holds maturing Blanton’s bourbon. The metal shell allows the building to quickly warm during the day and cool at night. These temperature changes allow the whisky to cycle within the barrel more often resulting in a smoother whiskey.

Most distillery warehouses leave the windows open in the summer then closed in the winter. In the case of Buffalo Trace they do not let the temperature in the warehouse fall below 45° degrees. Each floor of every warehouse is monitored daily and windows will be opened or closed depending on readings.

The opening and closing process is still done the old fashioned way by hand, even in the new buildings. In the case of the new 58,800 barrel warehouses, each one has 450 windows. Opening and closing the windows in one of these behemoths usually takes several days.

The heating system for the new warehouses on the farm is a natural gas fired patented heating system in the floors with dual zones so temperatures in each warehouse can be managed independently.

Master Distiller Harlen Wheatley Says Taste Profile Consistent Between Old and New Barrel Warehouses

What the distillery is most excited about though, is the taste consistency in the new warehouses when compared to Buffalo Trace’s warehouses on its main campus.

When your job is to oversee production for this many barrels of whiskey it’s a lot of pressure. The tricky part is you won’t really know for several years if the bets you placed today will pay offer in four to 25 years when your whiskey matures and is ready for bottling.

“Consistency in a taste profile is much harder to maintain than most people realize,” said Buffalo Trace Distillery Master Distiller Harlen Wheatley.

“Any time you bring a new element into the equation, it has the potential to change the result. We’ve worked very hard to ensure our new aging warehouses are consistent in the taste profiles for which Buffalo Trace Distillery is known. We test all barrels in the new warehouses every 12 months and run them through a full sensory analysis to compare them to our “standard” for that brand at the part in its aging cycle and also compare them against barrels which have been aging the same amount of time in our more established warehouses on our main campus. We’re really happy the taste is consistent across the board and look forward to being able to release them once they’ve reached their aging potential.

“Along the way, we’ll continue to monitor them and run tests as we do with all of our aging barrels to make sure they are meeting or exceeding brand standards of quality.”

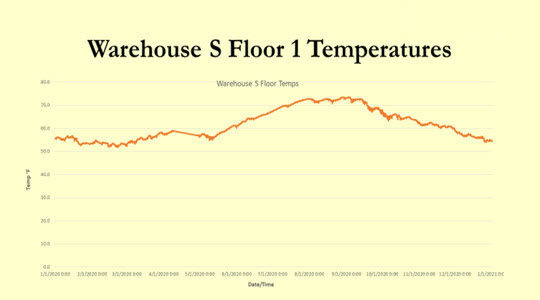

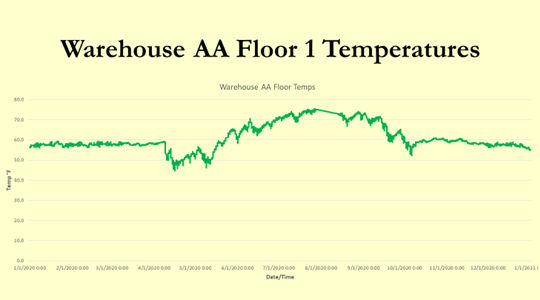

Buffalo Trace has been charting the progress of its new barrel warehouses for various elements, including temperature. The charts below compare the temperature inside in the first floor of barrel Warehouse AA, a “new” warehouse which holds 58,800 barrels, versus barrel Warehouse S, an “old” warehouse which holds 50,000 barrels, for the same time period, Jan 1, 2020 through Jan. 1, 2021. As the chart indicates, temperature fluctuation between the “new” and “old” warehouses is remarkably similar for the same time period.

“It’s reassuring to see the temperature fluctuations over the year remain consistent between the two warehouses, despite the location differences between the two warehouses. Through the years, we’ve gathered millions of data points on how the environment affects the whiskey inside the barrel. We know, for example, how important heating the warehouses are during the winter months, which is why we committed to continuing that tradition in our new warehouses we’re building. All of these data points give us great confidence that the bourbon we’re putting up today in our new warehouses will have the consistent flavor profiles our fans have come to expect,” added Wheatley.

Learn more about Buffalo Trace Distillery.

View all Kentucky Distilleries.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.