When you first approach Copper & Kings American Brandy Distillery it looks like many other distilleries. There are three copper pot stills with a beautiful patina finish, multiple condensers and spirits safes, bottling equipment, labeling and packaging machines and more. But, what you won’t find here that you see at most other distilleries are fermentation tanks and that’s by design. When making Brandy, you don’t use grains you use fruits, generally fresh fruits and lots of them. And I really do mean lots. It takes 5 tons of grapes to make one barrel of brandy. For Copper & Kings, the grapes come by way of California (some come from Kentucky but, we’ll get to that later) and the apples come by way of Michigan.

Serial Entrepreneur

Copper & Kings was founded in 2014 by Joe and Lesley Heron. The two are no strangers to startups. In 2002 they founded their first beverage company Nutrisoda which made a line of non-alcohol nutrient-enhanced sodas then sold it to PepsiCo two years later. In 2008 they founded Crispin Cider making hard apple cider and four years later sold that company to Miller-Coors. Copper & Kings is their latest venture.

Three Times a Startup

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Joe has worked with David Dafoe of Flavorman, a beverage development company for about 13 years. Flavorman is the flagship company for what is now the Distilled Spirits Epicenter. The Epicenter is made up of Flavorman, Moonshine University, Grease Monkey Garage and Challenge Bottling. Grease Monkey Distillery, which when not in use for Moonshine U classes, is available to develop mash bills, create prototype batches, experiment with processing, or for full run productions. Joe and David first started working together when Joe started Nutrisoda. They worked together again when Joe started Crispin Cider and most recently Copper & Kings. And before you ask (like I did), the answer is no, there are no artificial flavors or colors in any Copper & Kings spirits. The current relationship with David is now a long term friendship.

Head Said Go West, Friend Said Go South

When Joe and Lesley were starting Copper & Kings, the plan was to build their startup in the Pacific Northwest. They were looking at Tacoma, Washington and Portland, Oregon. All along the way, they were working with David on their brandy at Grease Monkey Garage Distillery. David tried to convince them to move to Kentucky from Minneapolis where they were living at the time rather than going out west. Joe was really serious about locating out in the Northwest. They had picked out a couple of locations, worked with the city to license a distillery but kept running into roadblocks. David kept telling them to move to Louisville, home of the Kentucky Bourbon Trail, the state responsible for distilling 95% of the world’s bourbon.

Serendipity – Location, Location, Location

“Our plan was to move out west to Tacoma. We got pretty far down the road. We were doing some pilot distillation here in Louisville and Dave suggested we come here. We were experimenting with different grape varietals and things like that and he said to come to Kentucky and we were like ‘No way.’ And then, the more we thought about it, being an American brandy anchored in American distilling country was really a very powerful concept and cultural anchor. We don’t make Cognac style brandy, that’s not our deal. We make American style brandy and being in Louisville is very helpful for that. Vendome Copper & Brass is three blocks away, we have Kelvin Cooperage, we have relationships with distilleries and being part of the Kentucky Distillers Association is very helpful. The city (Louisville) was very helpful, accommodating and welcoming. Those are the things that are important. And it turned out to be the smartest thing we ever did.

We were driving home from Louisville to Minneapolis and I called David and said, “David, F.U. we’re moving to Louisville.

Serendipity is a very underrated fact of life. Things happen and you get lucky and being here was the luckiest thing the ever happened to us. It was from a positioning of American Brandy the sweet spot, from a skills point of view a sweet spot. Guys like me and Les don’t build distilleries, you need an engineer and we got Pete Kamer of Distillery Engineering, who worked at Barton Brands, a super nice guy, and he was a genius engineer. That’s how you build a distillery, you get a genius engineer so that you build a world class facility, not a jury rigged distillery.”

A Craft Spirits Rock N’ Roll Brand was Born

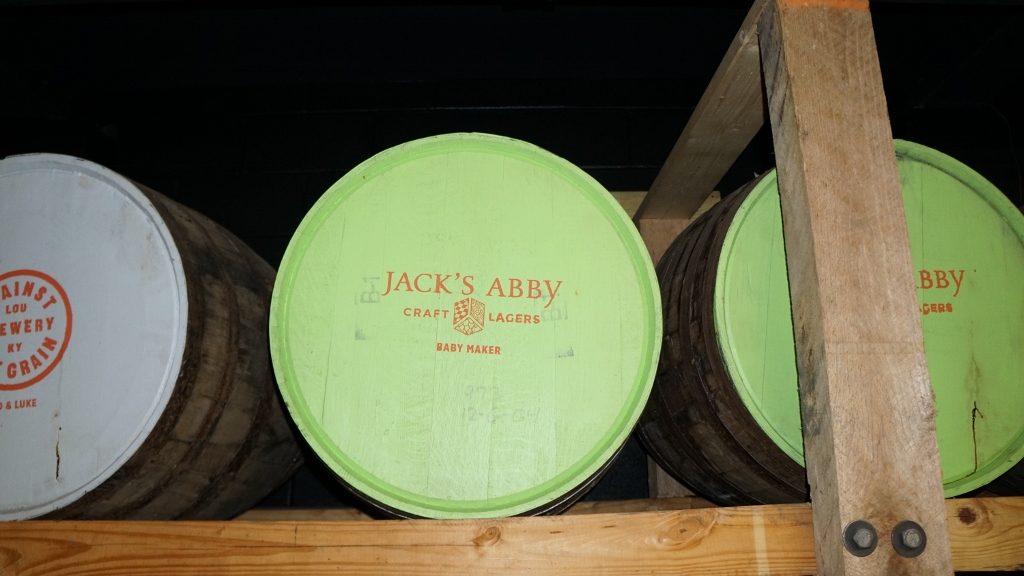

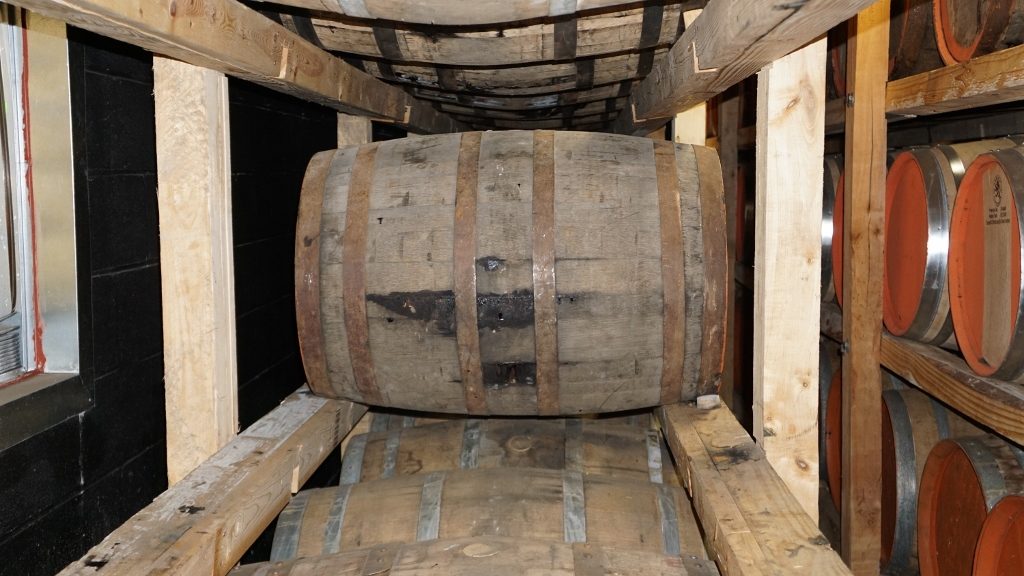

The Copper & Kings American Brandy Distillery is more than just a distillery, it’s a brand, a destination, an experience. It’s a craft spirits startup that’s not into following the herd. They’re not following any standard pattern of reselling other peoples bourbon or rye, they’re not selling moonshine, they’re making brandy, their own unique American Brandy. They are producing both unaged and aged spirits. And they have variety, about nine varieties today plus many special blends that come from experimenting with barrels on the back end. They are good friends with many distilleries and breweries. They are finishing their American Brandy, Apple Brandy, Absinthe and Cr&ftwerk in a variety of new white oak barrels, used bourbon barrels, used wine barrels and used beer barrels (see the photos below.) A walk through the distillery basement, home to their barrel warehouse reveals brand new oak barrels as well as used barrels from 3 Floyds, Sierra Nevada, Oskar Blues and Against the Grain just to name a few.

The Difference between Whiskey (Bourbon) and (American) Brandy

Living in bourbon country, I’ll bet Joe gets the “What’s the difference between Bourbon and Brandy” half a dozen times a day. Just before I asked the question a distillery visitor walking across the 16,000 square foot patio asked his own version of the Bourbon vs. Brandy question. It was perfect timing.

“I think you’ll find our brandy different. We make brandy in the way that bourbon is made and we often age in bourbon barrels. We don’t dilute in the barrel, we don’t chill filter which leaves a lot of the character of the fruit and the barrel within the distillate. Making whiskey is a process of extraction and purification to palatability whereas brandy is a process of retention and concentration; you are trying to keep the nuance of the fruit inside the distillate. We spend a lot of time on that. Our brandy is a little more spicy, a little more feisty, a little more whiskey like. We don’t even enter it into competition because we make an American brandy. Our reference points are American whiskey, not cognac. If you ask us what we like, I think Armagnac fits more to our profile which has a little bit more character and personality vs. an even keel enjoyment. Brandy has for years had a good start and a long finish whereas we like a little more feistiness and rambunctiousness. The actual process of distilling is the same.”

As the conversation wrapped up, the visitor shared with us that he had recently opened a small brewery in northern Indiana. Joe let him know that Copper & Kings works with many brewers to share used barrels for aging brandy and vice versa. The brewer said if he ever had enough “drums, I mean barrels” he would let Joe know and maybe they could trade barrels. That little drum slip prompted this little story from Joe.

“We do an April Fools release every year. We did this release that said we were launching a Rum made with 51% corn and Cabernet grapes and aged in a West Texas Intermediate Barrel (which is crude oil.) Then we got a call from the head of a major association and he wanted to know why it was called a rum and how long we were going to leave it in the barrel. Nobody got the joke!”

Related Story: What is Brandy?

Sonic Boomin’ Barrel Maturation

Joe and all the folks at Copper & Kings are Rock n’ Rollers at heart. They love Rock n’ Roll so much that they’re boomin’ their maturing brandy barrels 24×7 with large sub-woofers strategically placed around the warehouse. If you want to know what tunes are rockin’ the brandy today, visit the distilleries home page and listen in to their Spotify tracks.

Copper & Kings Head Distiller, Brandon O’Daniel explains the process like this, “What we are doing is we have these large sub-woofers that are placed throughout this cellar. We are blasting constantly rock n’ roll music as loud as we possibly can. The purpose of behind this is to make that brandy that inside that barrel constantly spin so that the brandy that’s in the dead center spins to the outside and the stuff that’s on the outside spins to the inside. At full blast you can actually put your hand on our barrels, feel that barrel vibrate, pop that brandy bung and you’ll see that flicker and wave at you. It’s constantly turning. The scientific reason for doing this is so that we get the liquor to touch as much of the surface contact of the oak as possible so it’s always breathing in and out through barometric pressure. And by constantly pushing frequencies through there it’s always changing so I don’t have anything sitting still. Everything is always moving.”

They love their music so much that its woven into the fabric of the distillery everywhere you look. In fact, all three of their alembic copper pot stills are named after songs from Bob Dylan’s 1976 album Desire.

- Isis: 1,000 Gallons – Big, bold and robust distillate. Isis is the Egyptian Goddess Of Fertility.

- Magdalena: 750 Gallons – Elegant, full of character, lovely polish in terms of distillate.

- Sara: 50 Gallons – Sara is a mirror image of Magdalena in all ways. She is small, gorgeous and makes the prettiest, refined distillate.

No Fermentation Tanks on Site

The fruit fermentation doesn’t happen at the distillery, it happens closer to the source of the fruit in California for grapes and Michigan for apples. From a supply chain management point of view it makes more sense for the fruit to be processed and fermented at its source. This way, it reduces shipping costs since you are only trucking the juice and the spent fruit never makes it to the distillery so there is very little waste at the distillery.

Types of Grapes and Apples

Copper & Kings primarily use three grapes that are sourced in the Central Valley and Central Coast regions of California. They typically use the classic brandy varietals,

- (French) Colombard

- Muscat de Alexandrie

- and Chenin Blanc.

These grapes have intense aromatics, and high acidity, for a distillate that is crisp and bright with a lovely nose.

To keep life interesting for the distillers and to add to the companies Kentucky roots they also create an annual Kentucky Vintage Brandy using a Kentucky grown Vidal Blanc grape varietal. Sourcing grapes in Kentucky can be hit or miss as the climate can vary widely from year to year. It takes five tons of grapes to make one barrel of brandy. Here are the results of their homegrown brandy production over the last three seasons.

- 2013 – 1 Barrel

- 2014 – 1 Barrel

- 2015 – 12.5 Gallons (That’s gallons, not barrels.)

Copper & Kings apple-wine is fermented and sourced from Michigan and is selected for its fresh, crisp, high acid, highly aromatic character. The fermentations are done at a very low +/- 60F, with a superior yeast selected for high aromatic retention.

Chill Filtered vs. Non-Chill Filtered

You generally hear about bourbons that are chill filtered. After aging in oak barrels for many years the bourbon picks up anywhere from 50% to 75% of its flavor and all of its color from the barrel. When removing the liquid from the barrel it can be quite cloudy. Joe explains, “With chill filtration, you take the liquid down to 32° degrees Fahrenheit and that causes a lot of the oils to clump and you can extract those through filter pads. For us, what you’ve taken out is everything we were trying to keep in. So, we don’t chill filter anything, unaged or aged spirits. For us, that’s a very, very important paradigm.”

Distilling 9 Months Out of the Year

One of the other big differences between a bourbon and a brandy is Copper & Kings American Brandy is only distilled nine months out of the year. No distilling happens during June, July, August and early September. It’s generally too hot in the summer and the fruit supply is erratic. Joe said, “We don’t want to put too much heat on brandy.”

Looking Ahead – Sales Expected to Triple

At the end of the day, it’s all about the sales. As we recently reported, Copper & Kings American Brandy just expanded its distribution from 21 to 27 states. In 2015 the distillery sold 5,000 cases that number is expected to double in 2016 to 10,000 and triple in 2017 to 30,000.

For Copper & Kings, it’s good to be an American Brandy distillery in Bourbon country.

A Photo Tour of Copper & Kings American Brandy Distillery

Please help to support Distillery Trail. Like us on Facebook and Follow us on Twitter.