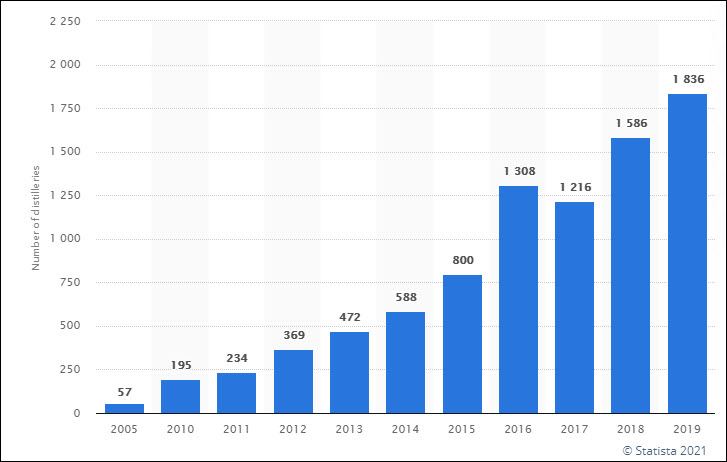

The number of distilleries operating in the United States has grown exponentially in the last 15 years. In 2005 there were fewer than 57 craft distilleries operating plus the traditional heritage distilleries that produce most of the spirits across the country. Today, the number of operating distillers has swelled to well over 2,000. Granted, the vast majority are producing small amounts of distilled spirits but the big companies have continued to grow and are producing more spirits today than ever before.

Just take a look at some of our coverage below over the last few months about the number of distilleries that have increased and in some cases doubled production to keep up with demand.

- New Riff Distilling Announces $2 Million Expansion – Will Increase Whiskey Production Capacity by 50%

- Woodford Reserve Distillery Announces Plan to Double Distillation Capacity at its Versailles Distillery

- Catoctin Creek Distilling Co. Tripling Capacity with $1 Million Distillery Expansion

- Kings County Distillery is Movin’ on Up as they Grow Capacity 5x

- Four Roses Distillery Celebrates Journey from Exile to Rebirth to $55 Million Expansion – Doubles Capacity

- Buffalo Trace Distillery Replaces 64k lb. 1950s Grain Dryer

- 4 Responsible Ways Distillers Use Spent Grains

In Kentucky alone the overall number of distilleries has grown 250% in the past decade.

More Bourbon Means More ‘Distiller’s Spent Grains’

In order to make all that bourbon and rye whiskey it requires acres and acres of grains like corn, rye, wheat or barley. With all of those grains going into whiskey production the spent grains or Distiller’s Spent Grains (DSG) has to go somewhere. As the volume of whiskey produced over the last 10 years has grown so has the amount of overall stillage. A lot of it is commonly used in the feeding cattle, dairy cows, swine, and some poultry. Most farmers are happy to haul the stillage away, often for free, to help grow their livestock. But, there are only so many mouths to feed.

Seasons matter too. In the winter when things are not growing in the fields spent grains are a welcome site to farmers but when the spring weather arrives and fields start to turn green the need for spent grains starts to go down as the herds return to greener pastures.

How Big is this DSG Issue?

Whether you are a craft spirits distillery or a large distillery the challenge of what to do with all those spent grains is a big question. For craft spirits makers that are doing small volumes it’s not necessarily an issue but for the larger distilleries, especially in Kentucky where the volumes are large and many distilleries are near one another what to do with Distillers Spent Grains is a major issue.

If the farmer does not show up to pick up the spent grains after two to three days it can actually shut down distilling operations. In other words, this is a huge issue.

For every gallon of bourbon produced, approximately 10 gallons of stillage remains, with an estimated 96 million gallons of stillage produced in Kentucky annually, that’s a lot of stillage. Currently, demand for stillage – including traditional low-tech uses – is declining as the supply of stillage continues to increase.

Have an Idea on How to Use that Spent Stillage?

It’s Time to Pitch It!

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Now, innovators and entrepreneurs can submit creative ideas, technologies and solutions for expanded uses of distilling byproduct. The top submitted ideas will enter a reverse pitch competition Oct. 25 during the 25th Distillers Grains Symposium in Louisville to an audience of distillers and industry stakeholders.

“Our state’s bourbon industry continues to grow at an incredible rate. That means more revenue coming into the state, more quality job opportunities for Kentucky residents and more global recognition for our outstanding brands,” Kentucky Gov. Andy Beshear said. “However, it also means a rise in byproduct within the industry, so we are asking people for their best ideas to use this stillage in ways that create jobs and moves Kentucky’s agritech industry forward. We’re building a sustainable economy that works for all Kentuckians, and that includes ensuring our industries operate as efficiently as possible.”

Individuals are invited to submit proposals by August 30, when five winners will be selected to present their ideas at the reverse pitch competition during the Distillers Grains Symposium. Leading up to the symposium, presenters will work with entrepreneurs and pitch experts to refine their pitches. Among other prizes, the pitch competition winner will get the opportunity to work alongside distilleries and stakeholders across the state to implement their ideas for surplus stillage usage.

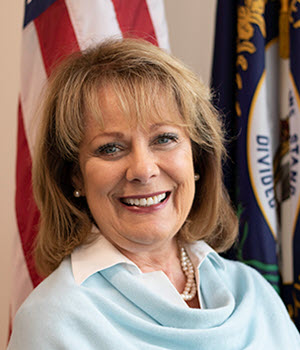

Kentucky Energy and Environment Cabinet (EEC) Secretary Rebecca Goodman said finding new uses for distilling byproduct builds on the Governor’s Kentucky AgriTech initiative.

“We are working closely with multiple stakeholders to find innovative and environmentally responsible ways to manage this increased volume of stillage,” Secretary Goodman said. “We believe it could be an integral part of the state’s agritech initiative.”

Glossary of Terms

- Dried Distillers Grains – DDG: Distillers grains can have some or all of the water removed making it dried, providing for a better shelf live and make it more feasible for travel.

- Wet Distillers Grains – WDG: Wet distillers grains are used for local farmers where the distance traveled is small. The weight of the water makes traveling long distances impractical. Because of the high water content wet distillers grains have a 3 – 5 day period before spoilage.

- Distillers Spent Grains – DSG: The spent or used grains that have been used to make distilled spirits.

Whole stillage, though mostly water, is acidic and has a high biological oxygen demand. Its useful life ranges from one to two days for wet – or thin – stillage before spoiling, to an extended shelf life for dried distillers grains. Current uses of stillage include animal feed and supplements.

Ideally, pitches should meet the following criteria:

- Prioritize sustainability and environmental impact;

- Demonstrate an economic value to the distillery and the end-user of the stillage;

- Identify the size of the distillery the solution is targeting;

- Address the location and space requirements of the solution, if any equipment or process footprint is required;

- Estimate product development costs, if applicable;

- Estimate the initial investment, ongoing costs and profits, if applicable, of the solution to the parties involved;

- Highlight the financial, sustainable and environmental benefits of the solution;

- Explain if/what testing or pilot demonstration has taken place and whether it was successful;

- Highlight the scalability of the solution; and

- Project the solution’s implementation/start-up time.

The reverse pitch competition will be hosted through a partnership between the Distillers Grains Technology Council, the James B. Beam Institute for Kentucky Spirits, Incubation Innovated, the EEC and KY Innovation, the Kentucky Cabinet for Economic Development, with support and guidance from the Kentucky Distillers’ Association.

Who’s Eligible to Pitch Ideas?

Solution submissions are open to anyone who has a potential viable solution for use of stillage and is committed to executing the solution. This includes, but isn’t limited to students, researchers, entrepreneurs, inventors, businesses, farmers and environmentalists.

Do you think you have what it takes to turn Distillers Spent Grains into gold? You can submit your ideas to the BourbonReversePitch.

View all Kentucky Distilleries.

View all U.S. Distilleries.

Looking for Grain Drying Equipment? Check our featured Grain Drying Solutions here.

Keeping Up with the Production Line

If you are a visual person trying to keep up with the volume of stillage coming through your distillery you may feel a bit like Lucille Ball. Here’s a classic snippet of what it’s like when the boss lady turns up the volume on production an the folks down the line aren’t prepared to handle it. Enjoy!

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.