One of the great things about distilled spirits like bourbon, rye, wheat, or malt whiskey is there are very specific rules about what you can and cannot put into it during the fermenting, distilling and aging process. We won’t go into all the details here, but we’ll highlight two of the key attributes in that it must be made in a new charred oak barrel (container) and it must be free from additives.

As a distiller these guidelines are helpful in that you know exactly what you must do to make a bourbon, rye, malt or wheat whiskey. On the other hand, some of these rules may feel restrictive when you have an idea of a flavor profile you want to feature in your whiskey, but you are not sure how to highlight that flavor within the guidelines.

One way to highlight different flavors is by using different types of oak barrels. Independent Stave Company has been making oak barrels and staves for the wine, beer and spirits industry for more than a century. As long-time industry experts Independent Stave knows a lot about how to toast and char barrels to pull out specific flavors that will end up in a whiskies finished product. They can control the amount of time used for a char the heat source for a toast and many other variables and now they’ve added a new process they refer to as Cold Smoked Barrels.

ISC Barrels Introduces Small Batch Smoked Barrels

ISC Barrels has introduced the Small Batch Series with the addition of a new line of Smoked Barrels. Recognizing the increased popularity for spirits with “smokey” character they’ve developed a barrel that offers smoke characteristics that are not achievable by traditional toasting or charring methods.

“We saw an opportunity in the market to expand our portfolio of barrels using different wood sources to achieve desirable smoke characteristics,” said Independent Stave Company CEO Brad Boswell. “You’re seeing smoke used in innovative ways to influence cocktails and food, like the ‘smoked cocktail’ being reintroduced in bars and restaurants.”

What is a Cold Smoked Barrel?

Independent Stave Company has developed a unique, proprietary barrel smoking technology and process. During this process, no flame, heat, or smoking material comes in contact with the barrel. This is known as a ‘cold smoking process’.

According to Independent Stave Company Director of Spirit Research and Innovation Andrew Wiehebrink they started developing this new process about two years ago. After extensive testing in the lab, four different trials, and the development of their proprietary cold smoking apparatus these barrels are now available.

“We often get requests from customers asking us to construct barrels made from their locally sourced wood. Often, we can’t meet these requests due to our manufacturing standards and physiology of the wood in question. Now, with our smoking process utilizing wood chips and other organic material, we can give our customers an avenue to integrate local materials into their products.”

The initial product release will feature the following types of 53-gallon Cold Smoked Barrels.

- Apple Smoked – Baking spice and estery top notes are complemented by a delicate floral-like smoke character.

- Hickory Smoked – Autumn campfire and toasted oak are paired with an intense and sweet BBQ pit smoke character.

- Maple Smoked – A balance of caramel and vanilla sweetness accompanied by a sweet and creamy smoke character.

- Peat – Two peat smoked barrels will be offered: Sweet Peat and Traditional Peat.

Customers will also be able to provide their own smoking material given that it fits the specifications.

Each Smoked Barrel is paired with a custom toast profile that delicately accentuates the unique flavor and aroma characteristics of each wood species.

Independent Stave Shares Cold Smoked Barrel Test Results

“As coopers, we are always looking for new and innovative ways to deliver flavor using oak barrels,” said Wiehebrink. “In the current spirits climate, we felt there was room for a barrel that focused solely on smoke character. I believe it is a flavor that has a lot of utility. Smoked cocktails, BBQ, smoked distillers’ grains – it is a universal tool for flavor development in many different areas.

“While it’s possible to get plenty of smoke character from the toasting and charring process, or by smoking distillers’ grains, there are restrictions with these methods.”

The variation in smoke character is limited due to the physiology of oak itself. Our Smoked Barrels allow distillers to add various smoky nuances into their products using a combination of different smoking material (ex: apple wood, maple wood, hickory wood) and toast profiles designed specifically for each material.

By smoking the barrels and not the grains, it allows for much more flexibility in the production process. Obtaining smoke character by smoking grains means that entire distillation batches must be dedicated to this flavor profile. Using barrels to add smoke makes blending and controlling the intensity of the smoke character simple and efficient. Running smoked grains through a distillation system can also come with other issues.

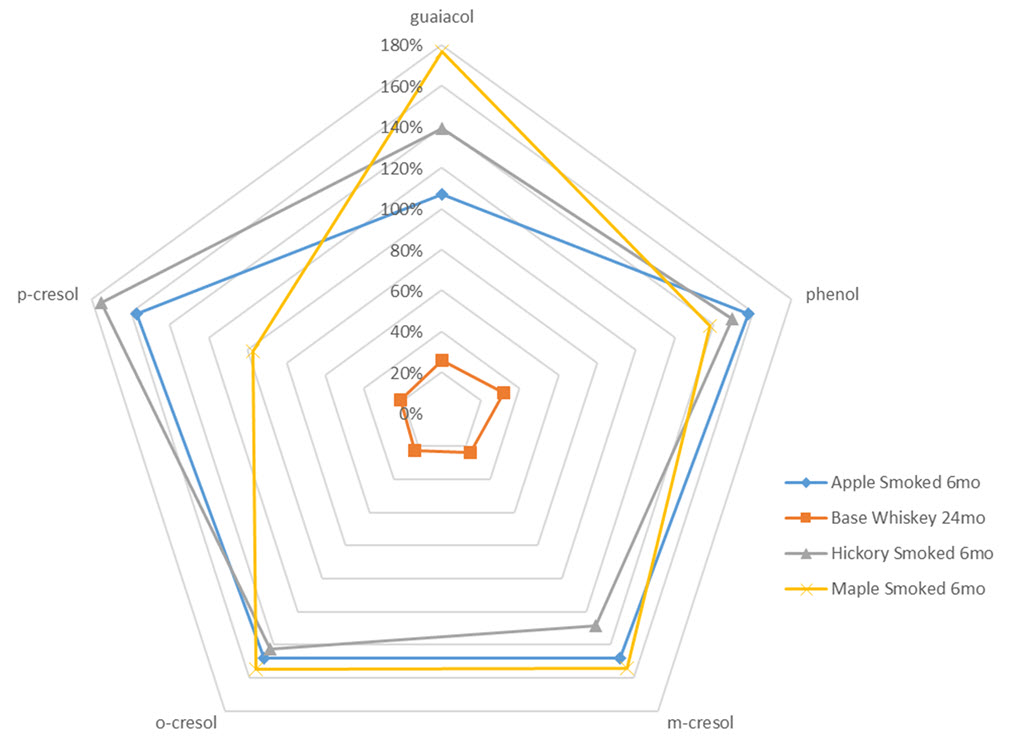

The process they use to manufacture these barrels ensures significant smoke character is delivered to the product being aged in the barrel. The figure below shows the results from one of the developmental barrel trials in which the Smoked Barrels were used in a finishing process with two-year-old bourbon. The bourbon was finished for six months. You can see the standard base whiskey featured in the center in orange at the 24 month mark. Then you can see the dramatic difference of the apple, hickory and maple cold smoked barrels.

Figure 1: Smoke component concentration after six months in secondary barrel.

Figure 1: Smoke component concentration after six months in secondary barrel.

“The increase in concentration of key smoke components in the finished whiskey is significant,” explained Wiehebrink. “In order to isolate the addition of smoke components due to the smoking process itself, we also placed barrels in this experiment that featured the same heat treatment as the Smoked Barrels but did not undergo the smoking process.

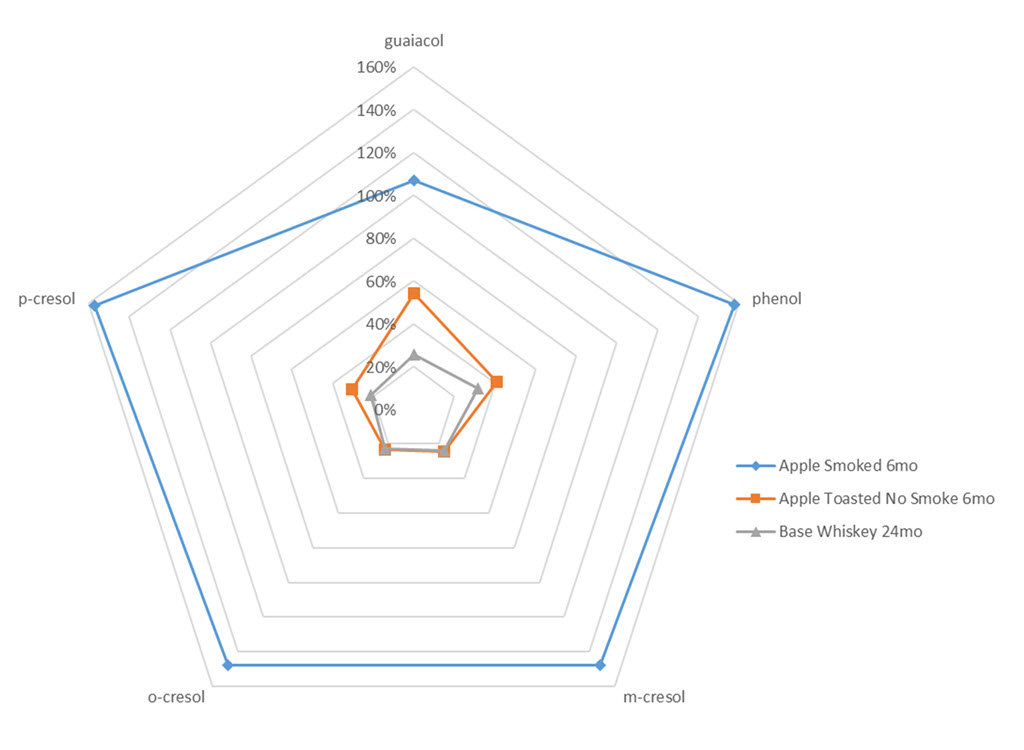

Figure 2 shows the results for the Apple Smoked Barrel versus a standard barrel. Results for both the Hickory Smoked and Maple Smoked showed the same results.

Figure 2: Apple Smoked vs. Apple Toasted without Smoke.

Figure 2: Apple Smoked vs. Apple Smoked without Smoke.

“We can see that the heat treatment associated with the Apple Smoked Barrel does give a small increase in the key smoke components, but the smoking process is responsible for most of the increase.”

ISC’s new Cold Smoked Barrels are offered in limited quantities. The Small Batch barrels series includes Spiral Cut, Wave Stave, Toasted, and now Smoked.

Related Story

The Chemistry Behind The Whisky We Love So Much [Infographic]

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.