Summer is a time for BBQs, beaches, fireworks, farmers markets and of course whiskey. Well, let’s be honest, whiskey is good all of the time. If you’re in the business of making whiskey, summer is also often a time for shutdown. Its a time to clean, retool, rebuild and to get ready for another distilling season. With the boom in distilled spirits, a lot of distilleries are using this time to up their game and expand production capacity. Michter’s Distillery is one of the distillers about to enter their summer shut down that will use the time to expand capacity, not just a little but a lot.

I recently met with Michter’s President, Joseph Magliocco at Michter’s M2 Distillery in the Shively area of Louisville, Kentucky to learn firsthand about their expansion plans and to take a behind the scenes distillery tour. The Shively location is referred to as M2 because Michter’s actually has two distilleries. The other distillery known as M1 is currently under renovation. The M1 distillery is part of an $8 million investment along Louisville’s famous Whiskey Row. Once completed, Michter’s M1 Distillery will be a fully functioning micro-distillery that will be open for public tours and tastings. Renovation work on the 126 year old structure known as the Fort Nelson building has taken longer than expected due to major structural issues discovered during the buildings renovation. The Whiskey Row distillery is now expected to open in about 18 months.

The Three Phases of the Modern Michter’s Brand

Just like a cat has nine lives, the Michter’s brand has had many lives. You can trace the brands original roots all the way back to Schaefferstown,Pennsylvania in 1753. Michter’s pays homage to its history on every label where it states, “Distilled in small batches according to the Michter’s pre-Revolutionary War quality standards dating back to 1753.” We are not going to go back that far today, but we will dive into the last 20 years or so since Michter’s parent company Chatham Imports acquired the intellectual rights to the brand. In my conversation with Joe, here’s how he explained the three phases.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Michter’s Phase 1 – Non-Distiller Producer

“The first phase of production we had absolutely nothing to do with making the stuff. It was already made years before. Dick (Richard “Dick” Newman) and I went around Kentucky, Dick knew everybody. We said we wanted to buy 10 year old bourbon and 10 year old rye. The market for old stuff then was not like it is now. The market for Rye was non-existent. And so, everybody was happy to offload stuff. We tasted around from a lot of different great stuff and we basically picked the kind of stuff that we wanted to make ourselves.”

Michter’s Phase 2 – Our Own Recipe

“The next phase of production we worked with a Kentucky distiller where we had a confidentiality agreement where I can’t disclose who it was but, we worked with a Kentucky distiller for 10 years where a certain number of days were Michter’s days. It wasn’t like the first phase where it was made without our input, this stuff was made using the same yeast that we are using now, barreling at 103 proof, using the barrels we wanted and our own mash bill. So, technically we were a non-distiller because we couldn’t afford our own facility yet. I believe we were more like a chef that couldn’t afford his own restaurant kitchen yet that was cooking someplace else.”

Michter’s Phase 3 – Our Own Distillery

“We became a licensed distiller here in this facility (Michter’s M2 Distillery) where we have 67,000 square feet on 7.5 acres. We became a licensed distiller here in 2012. We really ramped up production here when we installed our big equipment in (October) 2014. And by the time Pam and Willie felt that they nailed down that what we were making here was the just like what we were making at the other place it was August 2015. It was August 2015 that we actually started barreling. (There are photo’s below of the first barrels of Rye and Bourbon.)We waited until the sensory and the gas chromatography–mass spectrometry, until the chemistry was right there with the stuff we were making elsewhere. The equipment had to be tweaked. By the time that sensory and the GC-MS analysis matched dead on, it was August. So when people say I can’t wait to taste what you’re making here I say, Go to the store and buy a bottle of US*1 Bourbon because it’s the same stuff.”

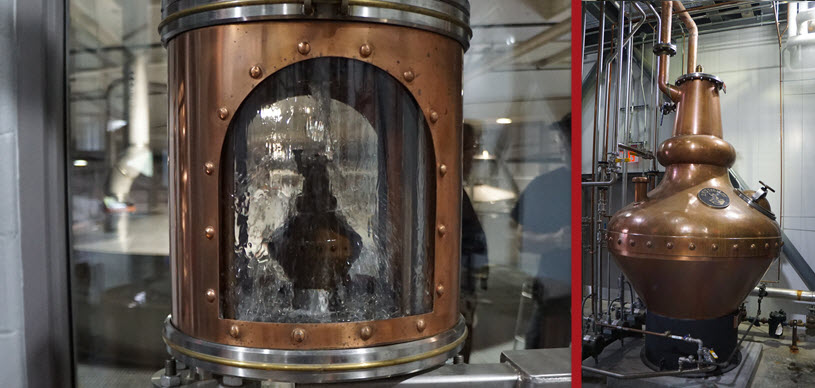

Michter’s Distillery 2014 Build Out

Michter’s M2 Distillery installed their big equipment in October 2014. The large tanks, cookers, fermenters and stills were all built by Vendome Copper & Brass Works. The 2014 distillation equipment was built using 11,051 pounds of copper, requiring 4,100 man hours to build and utilized 2,576 feet of copper condensing tubing. They installed four 16,000 gallon stainless steel fermentation tanks for a total capacity of 64,000 gallons. The continuous column still is 46′ tall with a 32″ diameter. It has 19 trays and four levels of unique copper grids. Many column stills are built out of a combination of copper and stainless steel but this still is kind of unique. Vendome and Michter’s decided to build the entire column out of copper to maximize the liquids contact with copper. This added to the cost but as Joe points out they believe the extra cost is worth to produce the best product possible. Their 250 gallon copper pot doubler still is 9′ tall by 5′ 6″ diameter at its widest point.

Expanding Distillery Capacity from 500,000 to 1,000,000 Gallons

Michter’s is currently operating at its maximum distillation capacity of 500,000 proof gallons per year. The American distillers’ standard measurement of alcohol production, a proof gallon is one liquid gallon at 100° proof at 60 degrees Fahrenheit. When the distillery resumes distillation in August after a month shutdown the distillery’s new distillation capacity will be 1,000,000 proof gallons per year.

Michter’s Vice President-Production & Distiller Pamela Heilmann explained, “By adding four more 16,000 gallon fermenters with a total capacity of 64,000 gallons and going to a second shift, we can make twice as much of the same great whiskey as we do now.” She said the current copper column still was designed with expansion in mind. It will be able to handle double its current production without any problem, in fact she said it was sized to handle as much as 1,500,000 million proof gallons. Sounds to me like they will be adding some additional fermentation tanks in the near future!

Here are a few insider photos from our tour of Michter’s Distillery.

Michter’s Distillery Photo

Please help to support Distillery Trail. Like us on Facebook and Follow us on Twitter.