Sellers Manufacturing is known throughout the distilled and craft spirits world for innovative design and manufacturing of the highest quality boilers, heaters, deaerators and related boiler room equipment, with unrivaled performance.

Steam System Basics: Why Steam?

There are three principal forms of energy used in industrial processes: electricity, direct-fired heat, and steam. Steam has many performance advantages that make it an indispensable means of delivering energy. These advantages include low toxicity, ease of transportability, high efficiency, high heat capacity, and low cost with respect to the other alternatives. Steam holds a significant amount of energy on a unit mass basis (between 1,000 and 1,250 British thermal units per pound [Btu/lb]) that can be extracted as mechanical work through a turbine or as heat for process use. Since most of the heat content of steam is stored as latent heat, large quantities of heat can be transferred efficiently at a constant temperature, which is a useful attribute in many process heating applications.

Since 1931, Sellers Manufacturing has been supplying the industry with the highest quality equipment with unrivaled reliability, efficiency, durability. Learn more here.

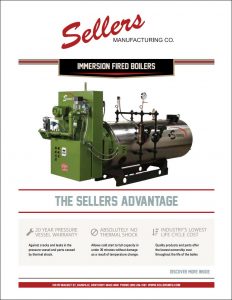

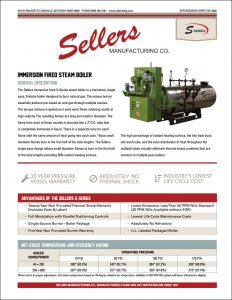

Sellers Immersion Fired Boilers

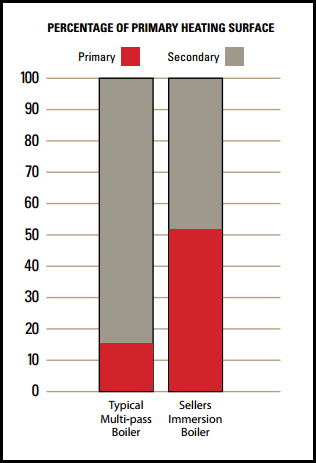

“In a Sellers boiler, 50% of the total heating surface is primary as compared to 5% to 14% in an ordinary boiler. This large percentage of primary heating results in balanced heat transfer and longer life.”

Research performed by the National Academy of Science, Report #44, determined that the amount of primary heating surface is the key to efficiency and long boiler life. Immersion firing gives you more primary heating surface than any other boiler on the market.

Built to Last

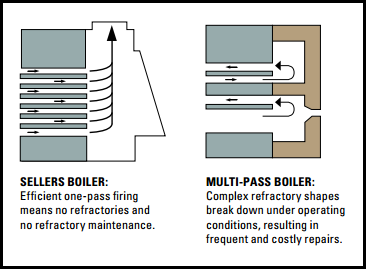

“The Sellers Immersion Fired Boiler Does Not Contain Refractory of Any Kind.”

In many multi-pass boilers, flame and hot gases are directed from pass to pass with special refractory. High temperatures and the stress of constant heating and cooling make for a short service life. Yearly maintenance and periodic replacement becomes a costly and time consuming requirement. These costs are completely eliminated with a Sellers immersion boiler.

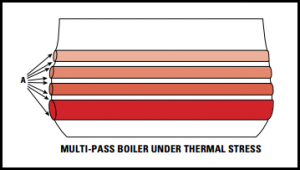

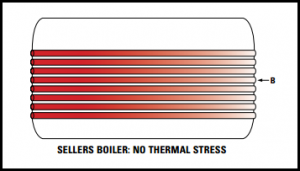

Sellers Eliminates Thermal Shock: Thermal shock can ruin a boiler. It is caused by the metal components in a boiler expanding or contracting unevenly. This can be caused by low feedwater temperatures, firing a cold boiler or uneven heat transfer rates across the heating surface. The result of thermal shock can be loose tubes, cracked tube ligaments or tube sheets. There are no thermal shock problems with the Sellers boiler. As shown in the graphic below, the single pass design eliminates the tremendous stresses that are associated with very high temperature differentials between the furnace and the successive passes of tubes in an ordinary boiler. Expansion is equal in all tubes, tube sheets are kept cool, and hot spots are eliminated.

SELLERS IMMERSION BOILER: Efficient one-pass firing means no thermal stress.

MULTI-PASS BOILERS: Increase thermal stress with each pass

Versatility

Sellers Manufacturing has a series of immersion boilers to fit almost any application.

Need Help Selecting an Immersion Fired Boiler for Your Distillery?

- Download the Sellers Manufacturing Immersion Boiler Spec Sheet here.

- Download the Sellers Manufacturing Immersion Boiler S-Series Spec Sheet here.

- You can also call us directly at 859-236-3181.

- Visit our website at SellersMfg.com

Deaerators and Boiler Feed Systems

What is a Boiler Feed System?

A boiler feed system is an assembly that efficiently pumps feedwater into a boiler. Seller’s boiler feed systems help prolong the life of boilers and maintain peak efficiency. Additionally, they provide more economical options to deaerators.

What is a Deaerator?

Deaeration protects industrial steam systems from the effects of corrosive gases by reducing the concentration of dissolved oxygen, carbon dioxide and other non-condensable gases to a level where corrosion is minimized.

A dissolved oxygen level of 5 parts per billion (ppb) or lower is needed to prevent corrosion in most high-pressure (>200 pounds per square inch) boilers. While oxygen concentrations of up to 43 ppb may be tolerated in low-pressure boilers, equipment life is extended at little or no cost by limiting the oxygen concentration to 5 ppb. Dissolved carbon dioxide is essentially completely removed by the deaerator.

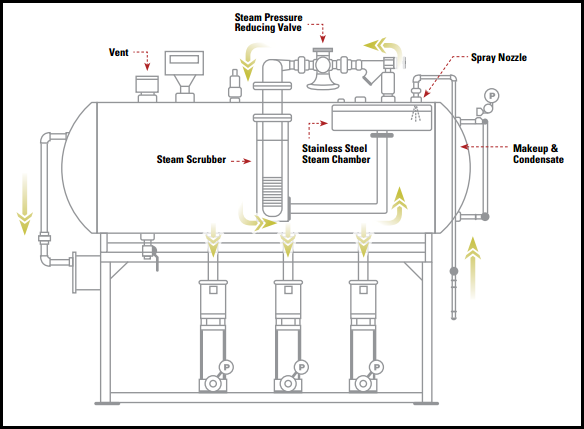

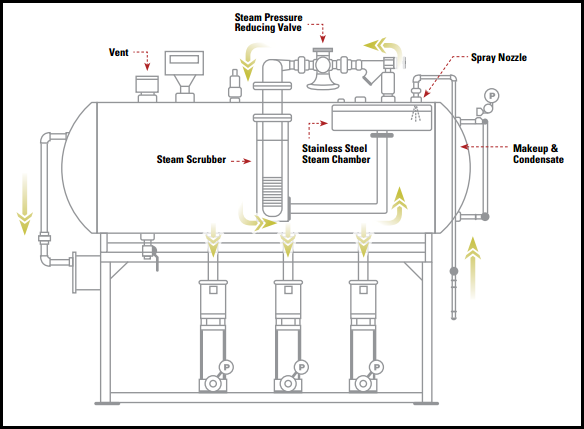

How Does a Deaerator Work?

- Raises the water temperature above the zero saturation temperature.

- Agitates to overcome surface tension.

- Atomizes water to smallest possible droplets.

- Allows time for gases to escape.

- Vents the gases from the system.

Need Help Selecting a Deaerator for Your Distillery?

Need Help Selecting a Deaerator for Your Distillery?

- Download the Sellers Manufacturing Deaerator Spec Sheet here.

- You can also call us directly at 859-236-3181.

- Visit our website at SellersMfg.com

Featured Products (Click Image to Download.)

Visit our site for all Product Specifications

Give us a call at 859-236-3181

and let’s get started with your project!

Since 1931, Sellers Manufacturing has been supplying the industry with the highest quality equipment with unrivaled reliability, efficiency, durability. Learn more here.

What is BrandScape? BrandScape is a way for product and service suppliers to talk directly to our audience. If you would like to learn more about BrandScape, please email Info@DistilleryTrail.com.