The Protectoseal Company is an engineering solutions company offering wineries and distilleries industry leading environmentally sensitive safety products. The company’s dedication to innovation continues since our founding in 1925.

The Protectoseal Company has a long and established history partnering with the wine and spirits industry to enhance operational safety and efficiency through product innovation and the promotion of industry best practices. Our work with the various international standardization bodies and an absolute adherence to ISO 28300 and API 2000 – Standards for venting atmospheric and low-pressure storage tanks as well as ISO 16852 – International standard for flame arresters, forms the cornerstone of our “Safety without Compromise” modus operandi.

Why Choose Protectoseal for Your Distillery?

While Protectoseal is known throughout the spirits industry for providing a broad line of standard devices, we are also experts in developing unique and effective solutions to address specific problems. Protectoseal welcomes the opportunity to apply our extensive technical and manufacturing experience to help distilleries face their most demanding application challenges.

Vapor and Flame Control Solutions for Distilleries

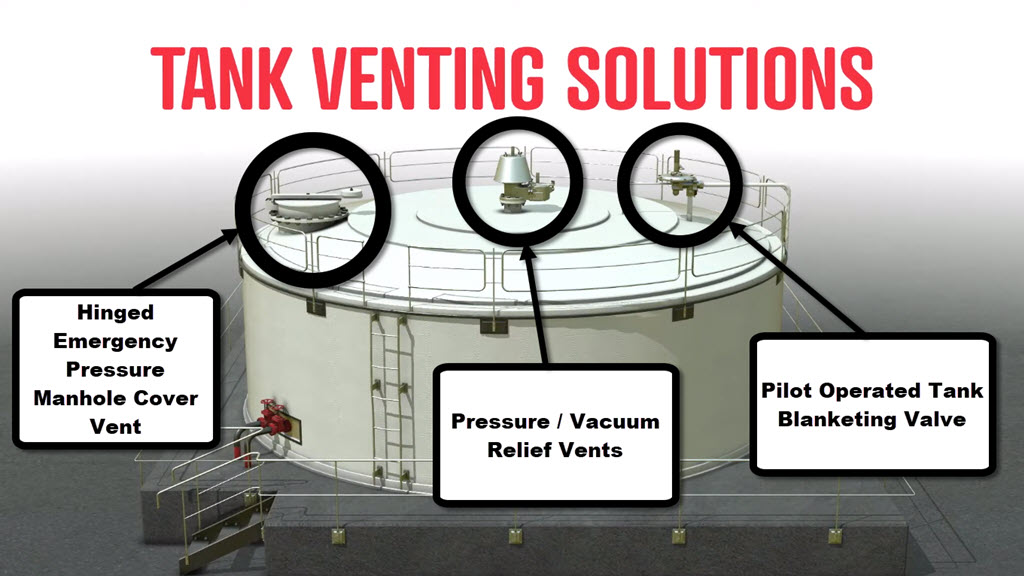

- Pressure and Vacuum Relief Vents

- Emergency Relief Vent

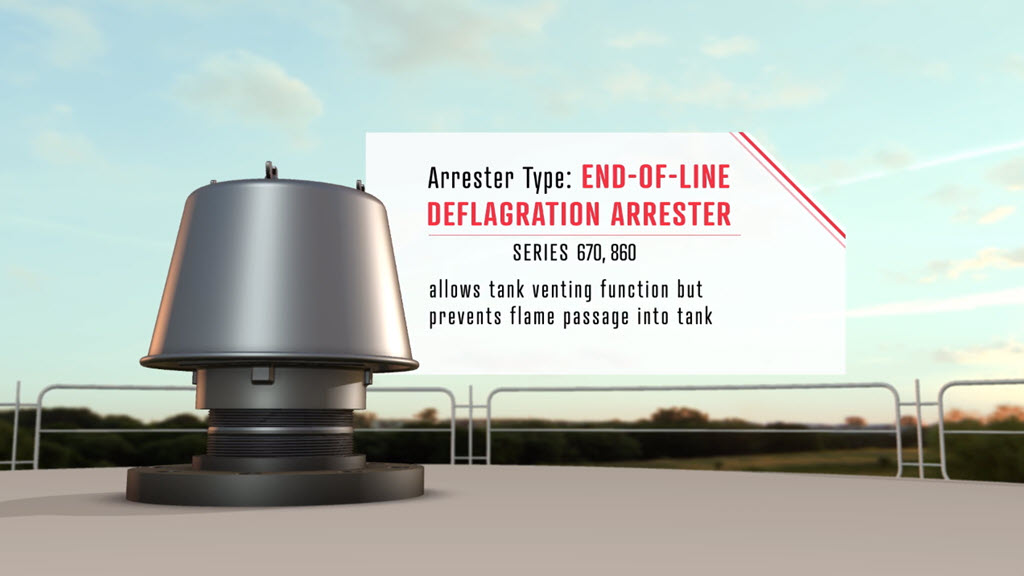

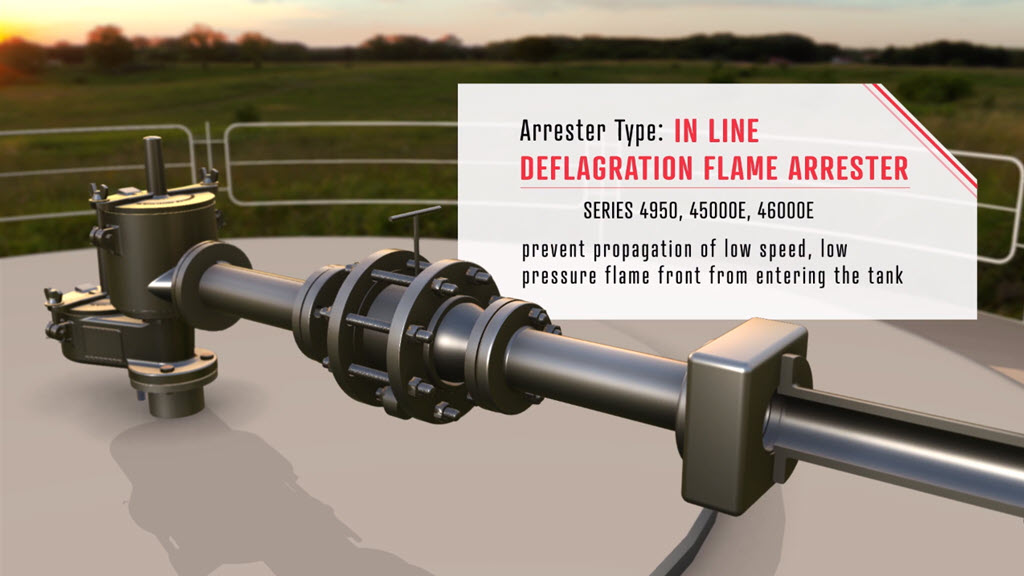

- Flame and Detonation Arresters

- Tank Blanketing Valves

Vapors released throughout the alcohol production process may present fire and explosive risks if not managed properly. Since complete avoidance of either flammable atmosphere or ignition sources may not be practical, explosion protection and isolation become necessary. The correct selection and proper use of venting and explosion isolation devices serves to help mitigate these risks.

Our pressure and vacuum relief vents, emergency vents and flame arrester product lines are integrated into distilleries worldwide to help safeguard against the hazards associated with the handling and storage of their flammable liquids. Protectoseal’s Series 830 Combination Pressure Vacuum Relief Vent and Flame Arrester offers a unique dual function design in an integrated, single body housing.

The Series 7800 Emergency Vent has exceptional flow performance, required to provide emergency relief capacity beyond that furnished by the pressure relief vent operating under normal conditions. Low leakage is achieved through the Air-Cushion Seat design – tested, certified with a test report accompanying each unit shipped.

In the ideal world, fire and explosive risks in distilleries can be eliminated by the avoidance of flammable atmospheres and/or avoidance of ignition sources. In the practical sense however, neither of these factors can be completely eliminated. Where a flammable or explosive environment exists, and an ignition source cannot be completely avoided, explosion protection with explosion isolation is required. The correct selection and proper use of venting and explosion isolation devices serves to help mitigate the overall risks. With over 95 years in the industry, we welcome the opportunity to work with clients to develop the most suitable vapor and flame control solution for their operational needs.

Distilled Spirits Application Challenge and Solution

The breadth of regulations associated with the construction and operation of distilleries are often complicated and not particularly specific to the industry. Of the relevant codes and standards, compliance to the National Fire Protection Agency’s Flammable and Combustible Liquids Codes (NFPA 30) and / or ATEX 1999/92/EC Directive is very important to ensure that the workplace is safe from fire and explosive risks.

Production of Alcoholic beverages can be classified into two major categories based on their mode of preparation: fermented beverages (e.g. wine and beer) and distilled spirits (e.g. whisky and brandy). In both cases, sugar from the raw material (e.g. grains, fruits, sugar can juice, etc.) is extracted and converted to alcohol and carbon dioxide through the fermentation process.

Distilled spirits undergo additional processing – specifically passing through the “still” where alcohol concentrations can be above 90% by volume (ABV). Vapors and gases released throughout the distillation and alcohol production processes may present toxic and explosive risks if not managed properly. Section 3-4.10.2 of the Recommended Fire Protection Practices for Distilled Spirits Beverage Facilities (published by The Distilled Spirits Council of the United States, Inc.) states that “each still should be protected for excess pressure and vacuum. It is recommended that all vents to the outside, and especially vents from vent condensers be equipped with flame arresters.”

Pure ethanol, the alcohol that is present in distilled spirits has a flashpoint (temperature at which liquids give off enough vapor to ignite in air) of 55 degrees F; an 80-proof distilled spirit contains 40% ABV and has a flashpoint of 79 degrees F – just above room temperature. With the distillation process itself requiring heat and taking into consideration other unintended ignition sources (e.g. mechanical / electrical generated sparks, static electricity, lightning, etc.) a potentially hazardous, flammable environment may be present.

“I wholeheartedly endorse Protectoseal. I have depended on their products, staff and the professional support of their entire organization for 10 years. ” – Director of Safety Wine and Spirits Company

To Find the Best Flame & Vapor Control System for Your Distillery visit Protectoseal.com.

Call 630-595-0800, email Info@Protectoseal.com or request a quote from Protectoseal.